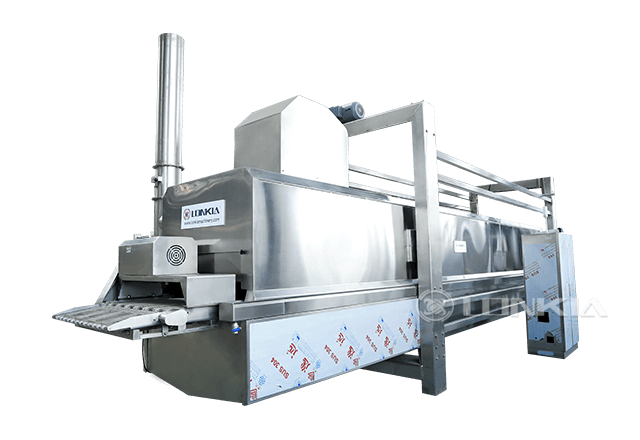

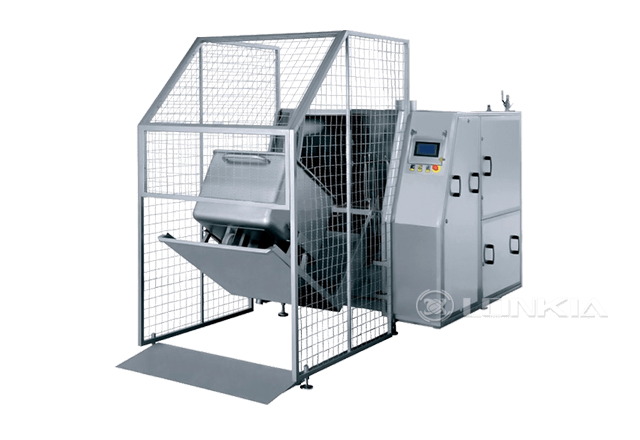

The tunnel steamer uses steam and hot air as a heat source to cook food, presenting a modern alternative to traditional high-temperature frying. Designed based on thermodynamics and food processing requirements, it is ideal for meat products. The tunnel steamer offers precise automatic temperature and humidity control, with adjustable steaming times. This method ensures food with appealing color and excellent taste, ready for packaging or further processing as semi-finished products.

Key Features:

Independent Steaming Zones: Two separate areas within the steamer allow for independent control of humidity via dew point regulation, and adjustable air circulation to meet specific steaming needs.

Optimal Browning and Baking: High-speed combined horizontal and vertical airflow during cooking achieves ideal browning and baking, maintaining crunchiness and product quality by preventing moisture loss.

Flexible and Consistent Cooking: Each cooking zone operates independently, providing flexibility and consistency. The use of lecithin during feeding creates a non-stick layer on the conveyor belt, enhancing product appearance and ensuring longer production uptime.