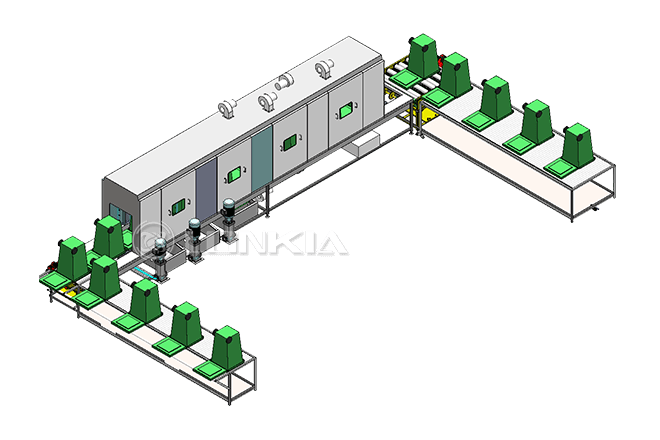

LONKIA's pallet washing machine is a fully automatic equipment that integrates cleaning and drying. It is mainly used for cleaning and disinfecting pallets used in industrial production, and is widely used in food processing factories, logistic centers, and other industries that require strict cleaning standards.

The workflow of this pallet washer is highly efficient and automated, completing the four steps of pre-rinse, main wash, rinsing and drying in sequence. Pallet through the conveyor system into the cleaning channel in turn, pre-rinse stage using high-pressure nozzles to remove surface impurities, the main wash stage through high-temperature water flow or special cleaning agent to rinse oil and bacteria, rinsing is thoroughly rinsed with water residual cleaning agent. Finally, The advanced drying system of plastic tray washing machine can quickly remove moisture from the surface of the tray to avoid bacterial growth, ensure product and food safety, and improve work efficiency.

The efficient circulating spray system can not only quickly and thoroughly clean the oil stains and dust on the pallets, but also improve the utilization of water resources and save costs. Therefore, it is especially suitable for deep cleaning of plastic pallets and trays, which helps to ensure the production environment hygiene and product safety. We also provide a tailor-made tray washer for pallet cleaning, support customized design, adapt to different pallet sizes and production line requirements, you can contact us at any time for more product details and solutions.