Fast and high quality

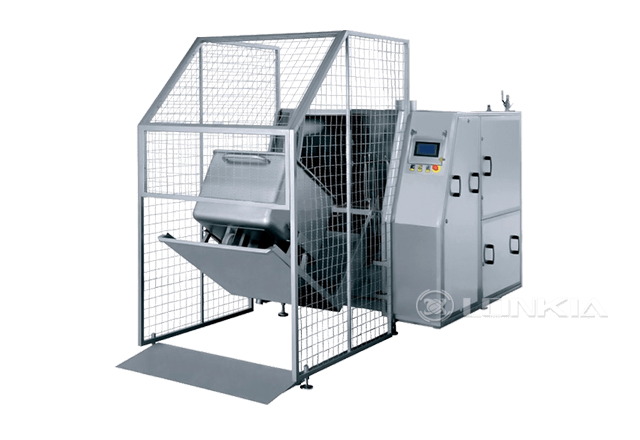

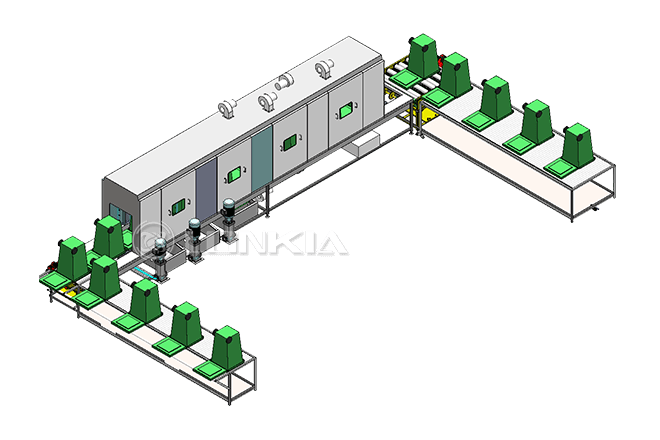

The limit rod in the tunnel is easy to adjust, and the width and height of the cleaning channel can be flexibly changed, so as to be compatible with barrel containers of various sizes.

Spray surround layout

The high-pressure nozzle adopts a surround layout, the spray angle is adjustable, and the bottom nozzle can swing at a large angle to ensure sterilization and decontamination without dead corners.

Safe bacteria control

The equipment focuses on sanitary protection and integrates multiple bacteria control designs. Multiple high-temperature cleaning processes and full-coverage high-pressure spraying ensure that the container is fully in contact with high-temperature water for more thorough sterilization.

Energy saving and consumption reduction

Mechanized large-scale cleaning effectively reduces staffing and labor costs. The fan used for air drying and drying is designed at the top of the tunnel, with high space utilization and reduced site occupation.

Email:

[email protected]