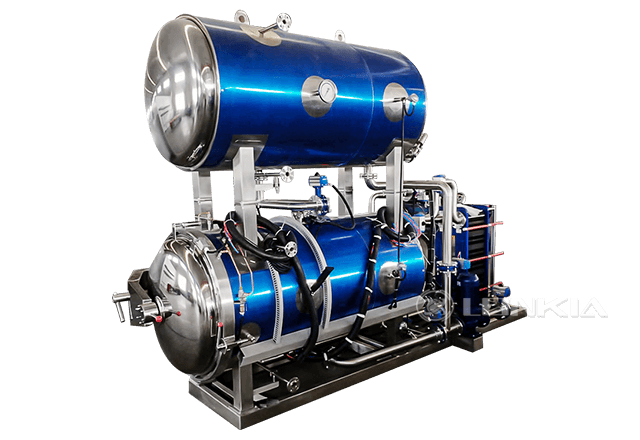

High Efficiency

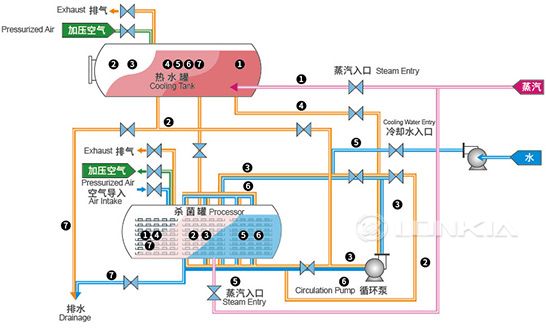

The sterilization water is preheated, and the starting point of the sterilization temperature is high, which shortens the sterilization time and protects the product quality.

Consistent Quality

The hot water after sterilization is recycled to the upper tank, saving steam, energy consumption and sterilization time.

Enhanced Safety

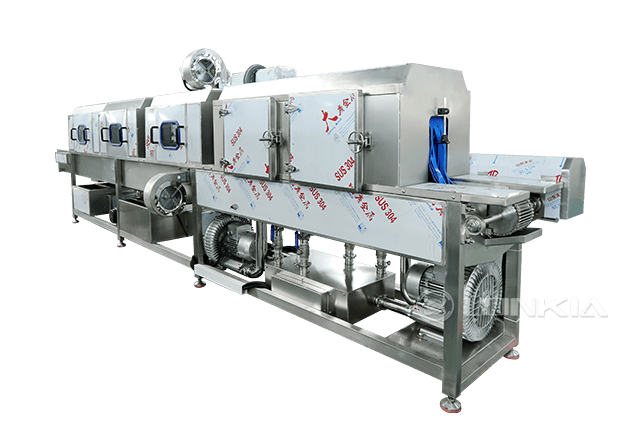

For flexible packaging products, especially bulk packaging, the heat penetration speed is faster and the sterilization effect is better.

Compliance

Can be equipped with F0 value control system to make sterilization more scientific.

Email:

[email protected]