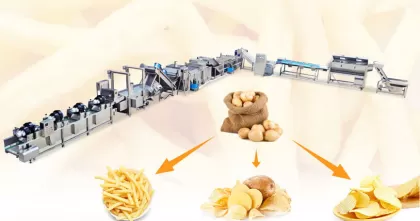

LONKIA crate washers seem like a reliable solution for maintaining hygiene standards in various industries that rely on containers and crates for storage and transportation. By focusing on both washing and rinsing zones, they ensure thorough cleaning, which is crucial for industries where cleanliness is a top priority, such as food processing.

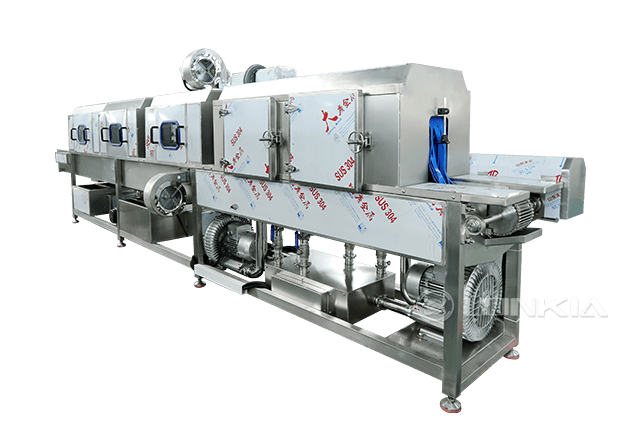

Lonkia industrial crate washing machines are ideal for food processing, agriculture, and logistics industries, offering advanced design and reliable performance. The conveyor system features speed reducers, chain rails, and limit bars for stable basket transfer. Equipped with high-efficiency nozzles and a multi-stage water system—pre-wash, main wash, and rinse—it effectively removes tough stains. The intelligent control panel allows flexible settings for wash time, conveyor speed, and operation mode, with built-in under-voltage protection.

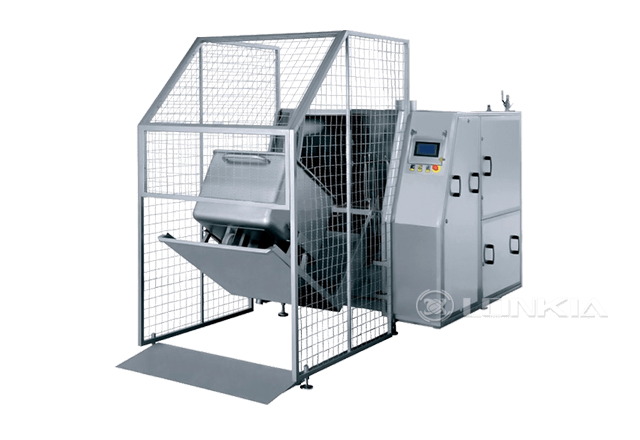

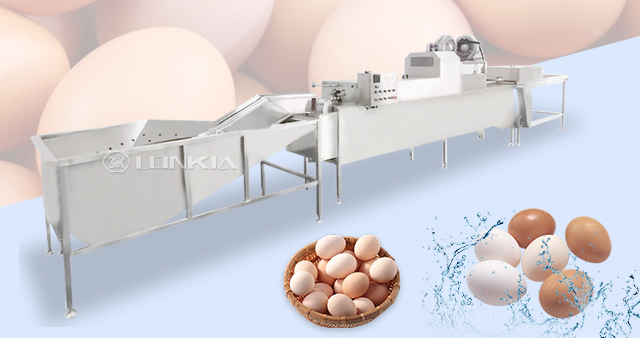

Additionally, as one of the best crate washing machine manufacturers, Lonkia crate washer's size and wash area can be customized to accommodate different crate sizes, including standard sizes like E1, E2, and E3, as well as custom sizes, makes them versatile and adaptable to various production needs. The emphasis on the latest technology suggests efficiency and effectiveness, which can translate to cost savings and improved productivity for businesses that invest in these washers. Lonkia has also launched a new advanced chicken crate washing machine solution designed specifically for the poultry farming and processing industry, further expanding the range of applications for its products in different industries.

Overall, LONKIA crate washers appear to offer a comprehensive solution for maintaining hygiene standards in industries that rely on clean containers, providing peace of mind for businesses and ensuring product quality and safety for consumers. To improve cleaning efficiency and optimize production processes, feel free to contact us for expert advice and customized solutions.