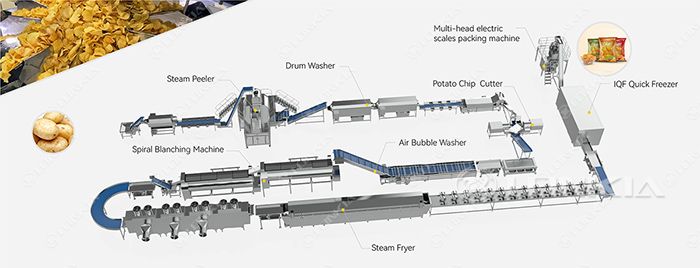

Starting a potato chip production line as a small business can be an exciting venture, but it’s essential to understand the various factors that influence the price of the equipment. In this blog, we’ll explore the key elements that determine the cost of potato chip processing lines and what small businesses should consider before making an investment.

Capacity Suited for Small Operations

For small businesses, the production capacity of the processing line is a major factor. Small-scale potato chip lines are generally more affordable and cater to businesses with lower production demands. It’s important to find a line that matches your current needs, leaving room for future growth without overwhelming your budget.

Automation vs. Manual Labor

The level of automation is another key pricing element. Semi-automated production lines are typically more cost-effective for small businesses, as they offer a balance between reducing labor costs and keeping the initial investment manageable. However, fully automated systems can offer long-term savings by maximizing efficiency, though they come with a higher price tag.

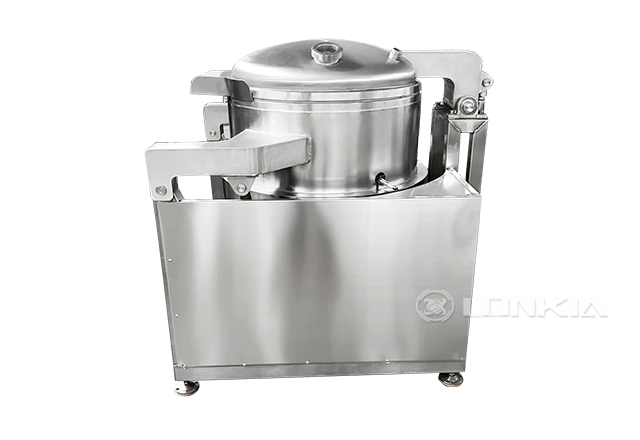

Material Quality and Durability

When choosing a potato chip processing line, the materials used in the machine’s construction will affect both the price and the machine’s longevity. Stainless steel equipment, known for its durability and easy maintenance, is generally more expensive but provides a longer-lasting and hygienic solution. Small businesses should consider this as a long-term investment to minimize frequent repairs or replacements.

Customization to Fit Your Needs

One advantage of working with a manufacturer like LONKIA is the option for customization. Small businesses often have specific requirements, whether it’s adjusting the layout, adding extra features, or optimizing the line for their space. Customization may increase the overall price, but it ensures the production line is perfectly suited to the business’s operational flow.

Energy Efficiency for Cost Savings

Energy consumption is an important consideration for small businesses trying to manage operational costs. Energy-efficient machines might come at a slightly higher initial cost, but the long-term savings on electricity bills can be substantial. Investing in energy-saving technology ensures that your potato chip production line is both eco-friendly and cost-efficient over time.

Installation and Support Services

Installation costs can also influence the overall investment. While some manufacturers offer basic installation, others, like LONKIA, provide comprehensive setup and training services, ensuring that your production line operates smoothly from day one. Additionally, after-sales support and maintenance packages help prevent downtime and keep the line running at peak performance.

Overall Cost Breakdown

The total price of a potato chip processing line for small businesses can vary widely. Basic models with essential features may start in a lower price range, while more advanced lines, including automated systems and custom designs, can be more costly. It’s important for small businesses to weigh their immediate needs against potential future growth when determining their budget.

In conclusion, the price of a potato chip processing line for small businesses depends on several factors, including capacity, automation level, material quality, customization options, and energy efficiency. By understanding these factors, small business owners can make informed decisions about their investment, ensuring they select the best equipment for their production needs. At LONKIA, we’re committed to providing flexible, high-quality solutions that cater to the unique requirements of small businesses.

This blog aims to help small-scale producers navigate the decision-making process, ensuring they find the right balance between cost and functionality. With the right potato chip processing line, small businesses can confidently scale their operations and succeed in the competitive snack market.