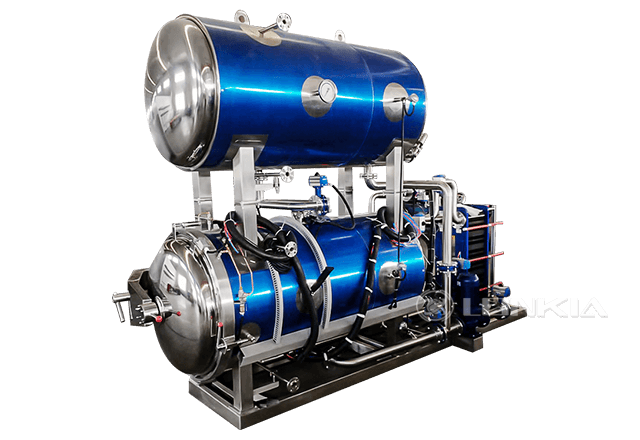

Low Temperature, High-efficiency Processing

Achieves effective sterilization at low temperatures while preserving the nutritional value and flavor of the product.

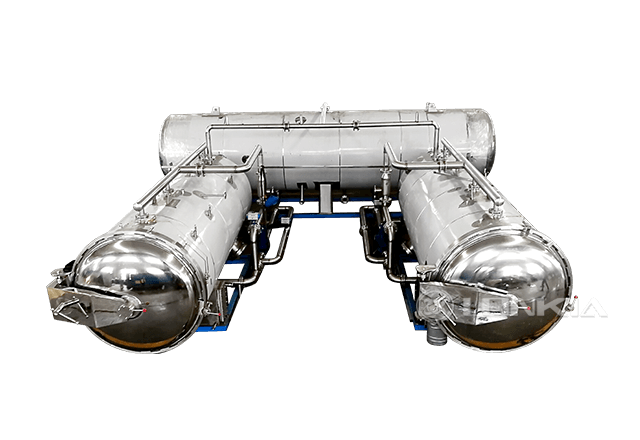

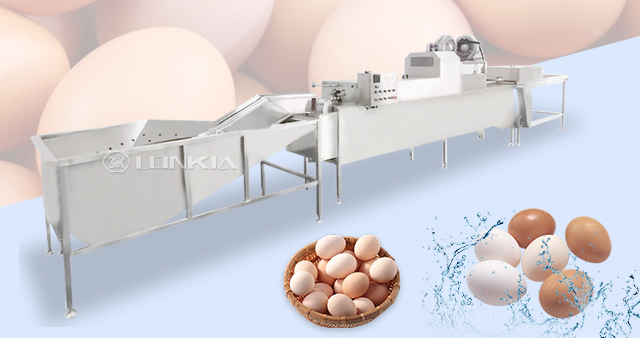

Applicable to Various Products

Suitable for a wide range of products, including liquids, semi-solids, and solids.

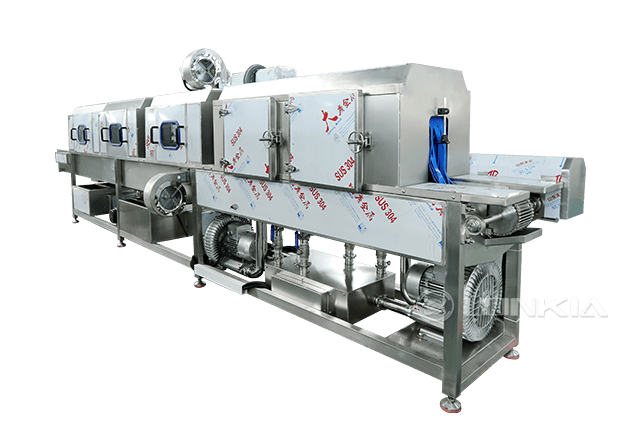

Extends Product Shelf life

By killing bacteria and microorganisms, it can prolong the shelf life of products, reducing the risk of food spoilage.

Energy-saving and Environmentally Friendly

Compared to traditional high-temperature sterilization techniques, the pasteurization low-temperature sterilizer consumes less energy.

Email:

[email protected]