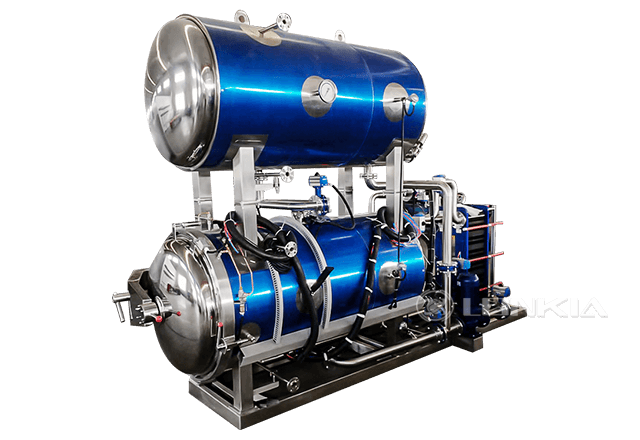

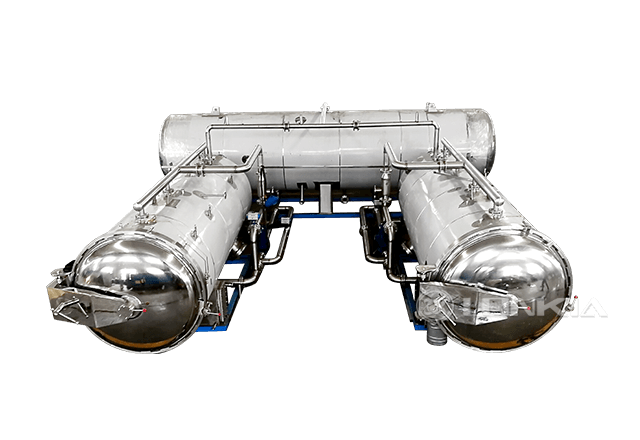

- Effective SterilizationThe vertical retort machine ensures thorough and even sterilization by using high-temperature steam and pressure, effectively killing microorganisms and ensuring that food products are safe and have a long shelf life.

- Preservation of Nutritional ValueBy using controlled heat and pressure, the retort process preserves the nutritional content, flavor, and texture of the food. This makes industrial steam sterilizer ideal for sterilizing delicate products such as vegetables, meat and seafood.

- High Production EfficiencyThe vertical retort machine is designed for large-scale production, allowing multiple batches to be processed simultaneously. This increases production capacity and efficiency, making it suitable for food processing plants handling high volumes of canned or packaged goods.

- Uniform Heat DistributionThe retort autoclave is equipped with mechanisms to ensure even heat distribution during the sterilization process. This eliminates cold spots and ensures that all areas of the packaged food receive the same level of sterilization.

Email:

[email protected]