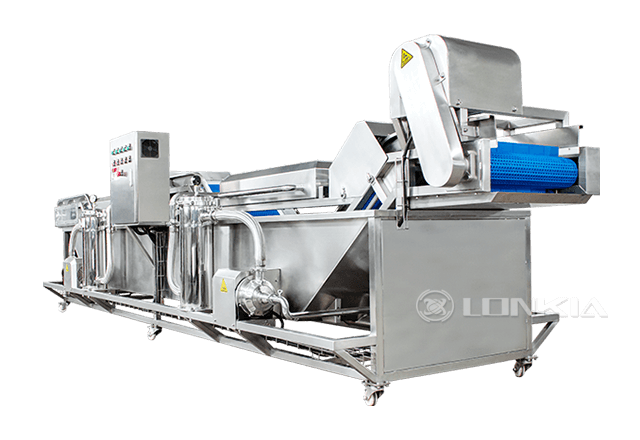

Efficient removal of residues

Combined with ozone technology, ozone has strong oxidizing ability and can effectively remove pesticide residues, bacteria and odors on the surface of vegetables, improving the washing effect.

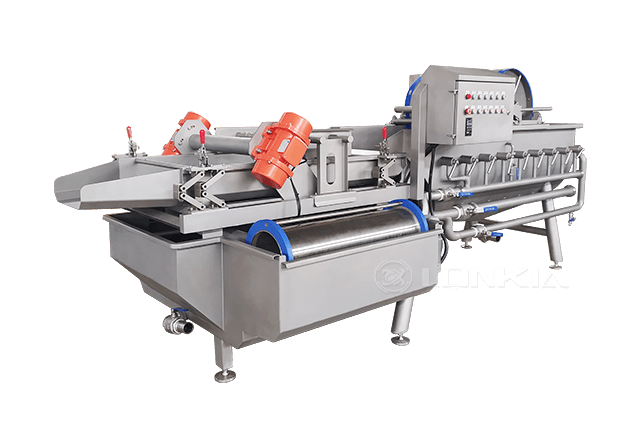

Advantages of slag discharge device

The equipment is equipped with a slag discharge device, which can promptly discharge sewage and impurities generated during the washing process, keep the washing liquid clean, and improve washing efficiency.

Fully automatic control

The equipment is equipped with an advanced PCL control system to achieve fully automated operation. It can be set according to vegetable washing requirements and is easy to operate.

Improve washing efficiency

During the washing process, sewage and impurities are discharged in time to maintain the cleanliness of the washing fluid, which can improve washing efficiency and ensure the quality of vegetable washing.

Email:

[email protected]