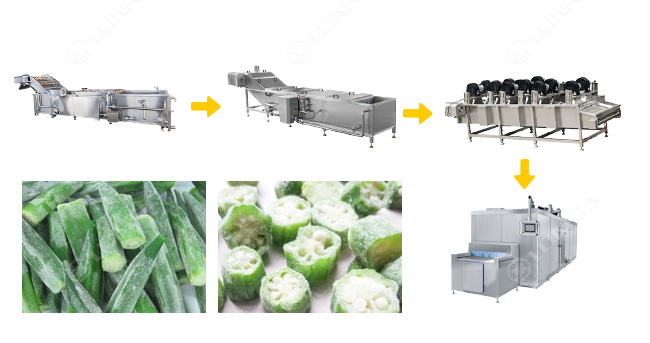

The Frozen Okra Processing Line is a highly automated and efficient system designed to streamline the production of frozen okra. This processing line ensures the preservation of okra’s natural color, texture, and nutritional value through advanced technology, while adhering to the highest food safety standards. It includes multiple stages such as cleaning, blanching, freezing, and packaging, providing a complete solution for industrial-scale okra processing.

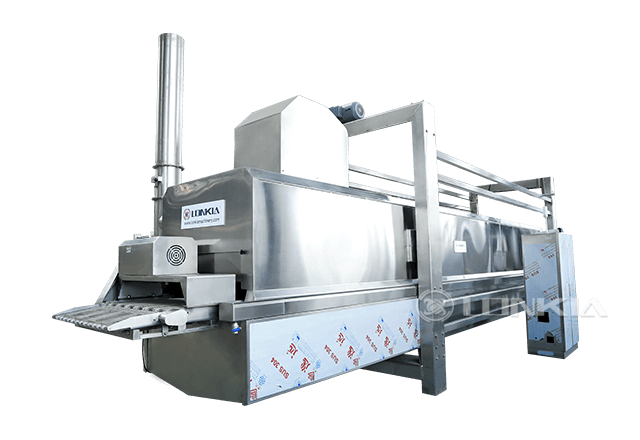

The Okra Freezing Processing Line employs advanced cleaning, sorting, cutting, and trimming technologies to produce uniformly sized, visually appealing frozen okra, meeting the quality demands of both retail and wholesale markets. First, the okra is fully cleaned by highly efficient vortex oscillation washers to remove surface impurities and pesticide residues and improve product hygiene standards.

Equipped with high-speed blanching and rapid freezing technologies, the system effectively preserves the okra's color, freshness, and nutritional value, reducing the risk of degradation. Optimized trimming and sorting modules raise the of Okra Frozen Production Line yield to 95%, ensuring consistent high quality. Additionally, the entire Frozen Okra Processing Line is constructed from antimicrobial stainless steel and features an automated CIP cleaning system, enhancing food safety, simplifying maintenance, and saving energy.