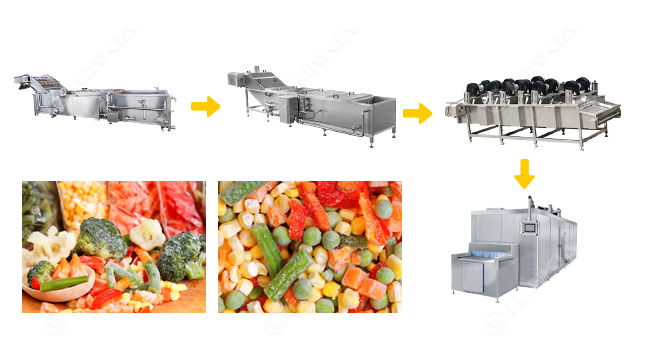

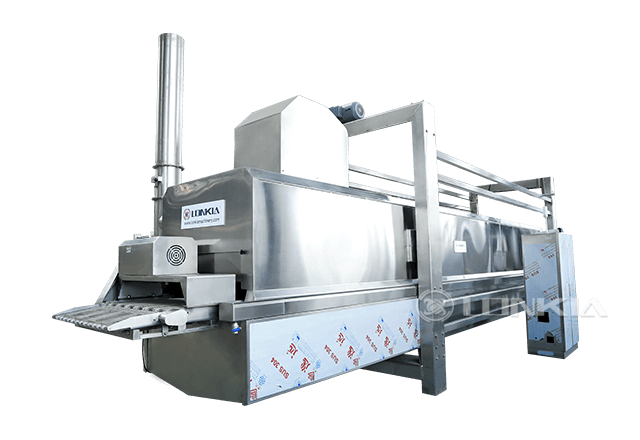

The frozen vegetable production line integrates the latest in food processing technology to deliver a seamless and efficient workflow. The process starts with a thorough cleaning of raw vegetables using leaf vegetables non destructive washer, followed by precise cutting and grading. Vegetables are then blanched to preserve their quality before being rapidly frozen using IQF (Individual Quick Freezing) technology, which locks in freshness. Finally, the product is weighed, packaged, and prepared for storage or distribution. This system is designed to handle a wide range of vegetables, ensuring consistent quality, safety, and efficiency at every stage of production.

The frozen vegetable production line employs an optimized freezing process to lock in the natural vitamins, minerals, and flavors of vegetables, ensuring both high quality and extended shelf life. The frozen vegetable processing line’s fully automated system—encompassing washing, blanching, freezing, and packaging—minimizes labor costs and boosts production efficiency. Additionally, frozen vegetable processing plant is versatile, capable of processing a variety of vegetables, including leafy greens, roots, tubers, and legumes, making it well-suited for diverse food service needs.