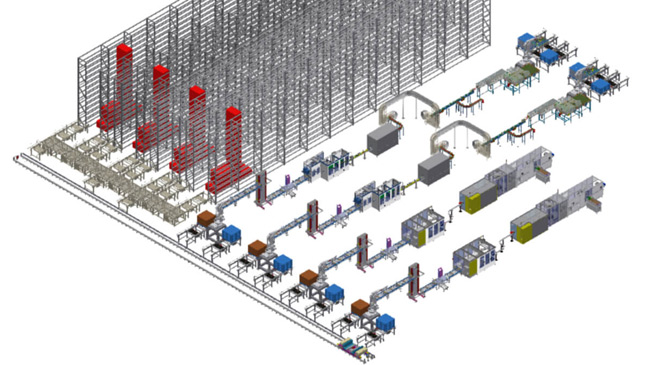

Palletizing robots can be seamlessly integrated into any production line, enhancing efficiency through intelligent, robotized, and networked production sites. These robots are adept at handling the palletizing logistics in various operations within the beer, beverage, and food industries. They are widely utilized for managing cartons, plastic boxes, bottles, bags, barrels, film-packaged products, and filling products. Equipped with advanced features like three-in-one filling lines, these robots can efficiently palletize different types of bottles, cans, and bags.

The automated operation of a palletizing robot encompasses several steps, including:

Automatic Box Feeding: Boxes are fed into the system automatically.

Box Transfer: The boxes are then transferred to the next stage.

Rowing: The boxes are arranged in specific rows.

Stacking: Boxes are stacked on top of each other.

Pile Transfer: The stacked piles are moved.

Stacking and Pile-Up: Continued stacking and piling up of boxes.

Feeding and Depalletizing: The stacked boxes are prepared for the next stage or unpacked.

A palletizing robot is designed to automatically perform these tasks, adhering to pre-programmed instructions and principles of artificial intelligence. These robots stack items, which have been loaded into containers, onto pallets (wood or plastic) following a specific arrangement. They can stack multiple layers of items and push the completed stack out for easy transfer to a warehouse via forklift.

The primary purpose of palletizing robots is to assist or replace humans in performing repetitive tasks, thereby improving efficiency and consistency in production, construction, and other industries.