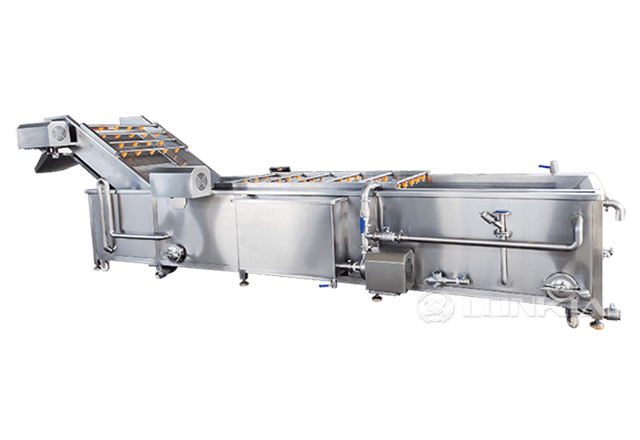

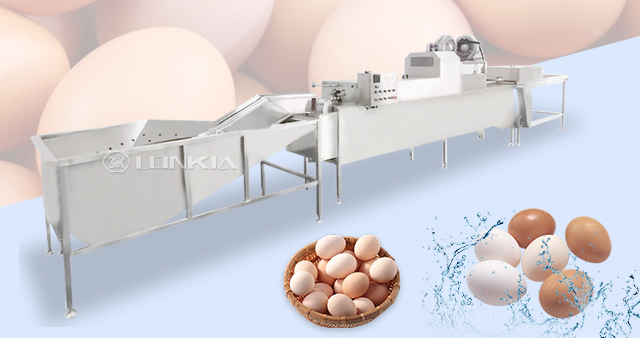

Bubble Washing

Utilizes water and air bubbles to gently agitate and remove dirt, debris, and contaminants from the surfaces of fruits and vegetables.

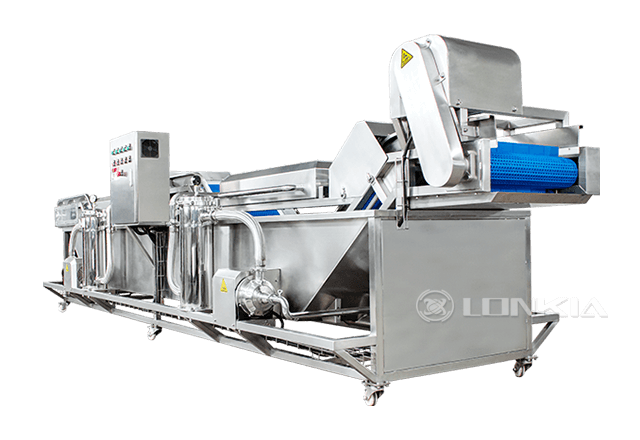

Adjustable Washing Intensity

Allows operators to adjust the intensity and duration of the washing process to suit different types of fruits and vegetables.

Water Recycling System

Some models come equipped with water recycling systems to minimize water consumption and reduce environmental impact.

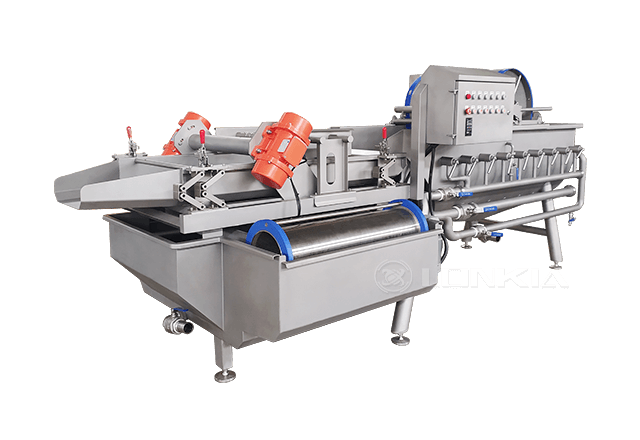

Sanitization Option

Offers the option to incorporate sanitizing agents into the washing process to further enhance hygiene and food safety.

Email:

[email protected]