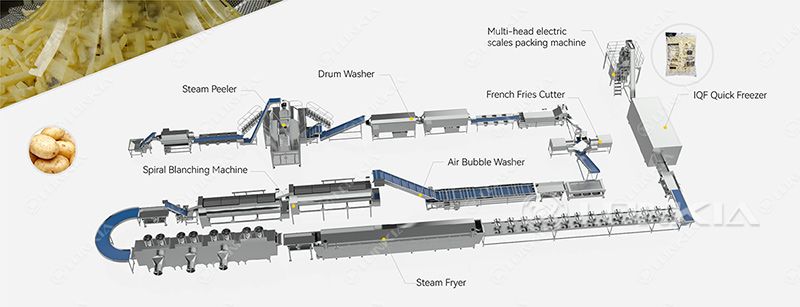

Frozen French fries are made through a multi-step process that involves preparing, blanching, frying, freezing, and packaging the fries for distribution. Here’s a step-by-step breakdown of how frozen French fries are typically made in industrial settings:

Potato Selection and Cleaning

The process begins with selecting high-quality potatoes, usually varieties with high starch content such as Russet potatoes. These potatoes are ideal for frying because they produce crispy fries.

The potatoes are washed thoroughly to remove any dirt, debris, and pesticides.

Peeling

After cleaning, the potatoes are peeled using mechanical peelers, which can be steam peelers or abrasive peelers. The goal is to remove the skin efficiently while maintaining the potato's shape and size.

Cutting into Fries

The peeled potatoes are then cut into the desired French fry shape and size. This is done using specialized cutting machines that slice the potatoes into uniform sticks or wedges. Common cuts include straight-cut, crinkle-cut, and shoestring fries.

Blanching

The sliced potatoes are blanched in hot water or steam. This step partially cooks the potatoes and removes excess sugars to prevent them from browning too quickly during frying.

Blanching also helps maintain the fries' color, texture, and flavor when frozen.

Drying

After blanching, the fries are dried to remove surface moisture. This step is essential to achieve the desired texture and prevent the fries from becoming soggy during frying.

Initial Frying (Par-Frying)

The partially cooked fries are briefly fried in oil at a high temperature. This is known as par-frying, where the potatoes are cooked just enough to form a crispy exterior while leaving the inside slightly soft. This step gives the fries their golden color and crispness.

The par-frying process typically lasts for about a minute or two at temperatures between 175°C to 190°C (347°F to 374°F).

Freezing

After frying, the fries are immediately cooled and frozen in a freezing tunnel to lock in their texture and flavor. This quick freezing process prevents the fries from sticking together and maintains their quality during storage.

The temperature inside the freezing tunnel is usually set below -18°C (0°F).

Packaging

The frozen fries are then packaged in bags or boxes, ready for distribution to retailers or foodservice companies. Packaging is done in a controlled environment to maintain product quality and prevent contamination.

The packaging is usually airtight to prevent freezer burn and extend the product's shelf life.

Quality Control

Throughout the process, quality control measures are in place to ensure that the fries meet the required standards for size, texture, and taste. Random samples are taken from each batch to check for consistency and any defects.

Distribution

Finally, the packaged frozen fries are stored in cold storage facilities and distributed to grocery stores, restaurants, or other markets. They are kept frozen throughout the supply chain until they are ready to be cooked by consumers or chefs.

Final Cooking

Once the frozen fries reach their destination, they can be fried or baked to complete the cooking process. The par-fried fries are typically fried at home or in restaurants until they achieve a crispy exterior and fluffy interior.

This process ensures that frozen French fries are convenient, consistent, and ready to be prepared quickly while maintaining the texture and flavor of freshly made fries.