As an important equipment in the food processing industry, the stable operation and long-term use of the French fries production line is crucial to the benefits of the enterprise. Good maintenance can not only reduce the failure rate, but also ensure product quality and production efficiency. This article will focus on how to scientifically maintain the key equipment in the frozen French fries production line, to help enterprises achieve long-term operation of the equipment.

Regular Cleaning Equipment to Maintain Hygiene and Efficiency

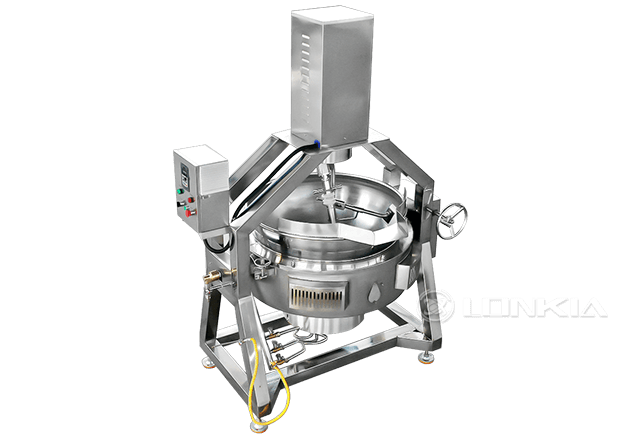

French fries production line involves peeling, cutting, blanching, deep-frying, degreasing and other links, each link needs to keep the equipment clean. Regular cleaning of debris on peelers and cutters avoids clogging and rusting, and the build-up of oil inside potato blanching machines and French fries fryers affects heating efficiency and product taste, so they must be cleaned in a timely manner. Lonkia's French fries maker machine is designed to be easy to clean, making it less difficult to maintain and improving production continuity.

Inspect Key Components to Prevent Wear and Damage

Critical parts such as conveyor belts, blades, motors, bearings, etc. are prone to wear and tear due to long-term use. Regularly checking the condition of these parts and replacing those that are subject to severe wear and tear can help prevent production interruptions. The core components of Lonkia's French fries production lines are made of high-quality materials that provide a long lifespan, but maintenance should not be neglected.

Proper Lubrication Extends the Life of the Machinery

During operation, bearings and chains need to be lubricated at the right time to minimise wear and tear. According to the equipment manual, the use of appropriate lubricants, and in accordance with the recommended cycle of lubrication, you can ensure smooth operation of the potato fries making machine, reduce the failure rate.

Electrical System Maintenance to Ensure Safety and Stability

The electrical control system in the French fries production line is responsible for the automatic operation of the whole line. Regularly checking electrical connections to prevent loosening and short-circuiting, and replacing old wires in a timely manner, ensures the safe and stable operation of the equipment. Lonkia equipment is equipped with an advanced electrical control system, which is easy to maintain, but still requires regular servicing.

Reasonable Maintenance Programme and Training of Operators

Formulate a scientific maintenance plan, specify the cycle of cleaning, inspection, lubrication, etc. to avoid omission. At the same time, strengthen the training of operators, improve equipment operation and maintenance skills, reduce the failure caused by improper operation.

Through the above methods, you can effectively extend the service life of the French fries production line and guarantee the efficient and stable operation of the equipment. Choose Lonkia's French fry production line, not only enjoy the advanced equipment, but also get professional technical support, to help enterprises achieve long-term development, Lonkia as a professional French fries production line manufacturer, to provide efficient solutions for your French fry production.