As an important equipment in the field of fruit and vegetable processing, mango peeling machine, with its efficient and precise peeling function, helps processing enterprises to significantly reduce the loss of fruit pulp and improve the yield rate. The following will introduce how the mango peeler machine realizes the goal of "reducing waste and improving yield" from the perspective of core technology and practical performance.

Precise Peeling Design Reduces Pulp Loss

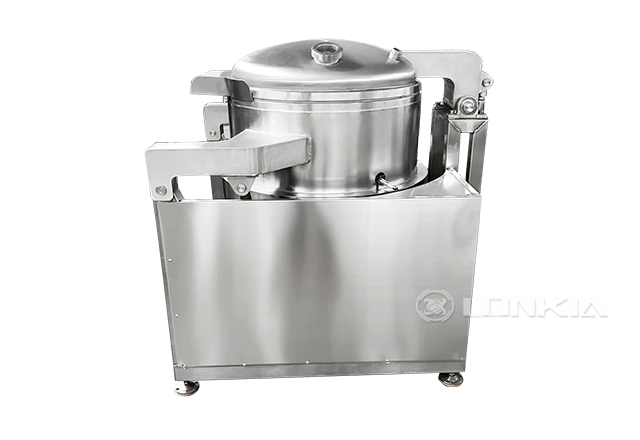

Modern mango peeling machine adopts adjustable cutter head and positioning device, which can automatically adjust the peeling thickness according to different sizes and shapes of mangoes to maximize the retention of pulp. With the help of high-precision sensors, the system detects the peel thickness in real time and compensates for it dynamically, so that the peeling effect can be kept stable without manual intervention. Lonkia's patented double-layer cutter design makes the peeling more even and leaves no peel residue, thus reducing the waste of pulp caused by secondary processing.

High-speed Automation Increases Productivity

The combination of the high-speed rotating cutter head and the automatic feeding mechanism allows the industrial mango peeler to process dozens of mangoes per minute continuously during peak operation. The automatic dregs discharge system can separate the peel waste in time to avoid the second accumulation of jam. The whole machine adopts PLC control panel, which is easy to operate, and can be fully automated after one-key start and parameter presetting, which saves labor cost substantially. Efficient production capacity is directly translated into increased output per unit of time, providing reliable support for long-term mass production.

Easy Maintenance Structure Ensures Stable Output

The overall structure of the mango peeling machine follows the design concept of "quick disassembly and quick installation", and the core components such as cutter head, cutter plate and conveyor belt can be disassembled and cleaned within minutes. The entire machine is made of stainless steel with smooth surface, corrosion resistance and food-grade hygiene standards, so the daily maintenance workload is extremely low, and Lonkia adopts reinforced and thickened materials in the key stress areas of the machine body to prolong the service life of the machine and minimize the loss of production capacity caused by downtime and maintenance.

Multi-scenario Compatibility and Modular Expansion

The industrial mango peeler can be easily interfaced with other production equipment such as conveyor lines, cutting machines, etc., to realize the integrated operation of the assembly line through modular interfaces. According to the demand of the production line, it can be equipped with intelligent sorting or filling units to meet the production demand of different scales and processes, further optimize the production process and improve the overall efficiency.

Through the comprehensive advantages of accurate peeling, high-speed automation and easy maintenance, the mango peeling machine effectively reduces waste, improves production, and brings higher economic benefits and production reliability for fruit and vegetable processing enterprises. If you would like to know more about the equipment or customized solutions, please contact Lonkia's professional team, we will provide you with one-stop technical support and after-sales service.