Frozen French fries have become a food product that continues to grow in demand in the global marketplace due to their convenience, taste and ease of preservation. More and more business owners and investors are looking to invest in automatic frozen French fries plant in their home country to cater to the local market or export business. In this article, we will explain in detail the steps involved in setting up French fries making machine factory in your country to help you get your project off the ground quickly and efficiently.

Understanding the Complete Frozen French Fries Production Process

The first step in setting up a successful automatic frozen French fries plant is to have a clear understanding of the entire process: from incoming raw materials, washing and peeling, cutting and shaping, blanching and color protection, frying, rapid freezing, and finally packaging. Each link needs supporting machinery and equipment to complete.

The main frozen French fries making machines include:

- Brush peeling machine: efficiently removes sediment and potato skin, and improves the efficiency of the subsequent process.

- French fry cutting machine: to ensure the consistency of cutting size and improve the uniformity of the finished product.

- Blanching machine: keep the color and structure of French fries stable through hot water treatment, which is conducive to the subsequent deep-frying;

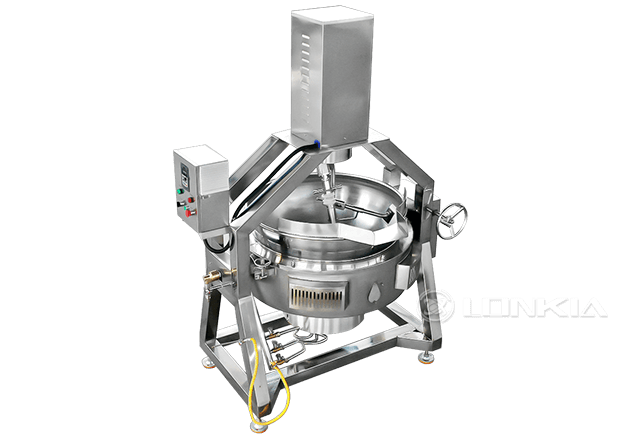

- Frying machine: uniform frying and shaping to improve the taste and appearance of French fries.

- Instant freezing facility (IQF): fast freezing to avoid sticking and ensure independent molding of the product.

- Automatic packaging machine: automated encapsulation to effectively extend shelf life.

Lonkia, as a mature frozen French fries production line manufacturer can provide the whole line of equipment and technical solutions to meet the needs of users in different countries.

Site Selection and Infrastructure Preparation

The layout of the plant should be reasonably planned according to the volume of the equipment and the operation line, to ensure that the cleanliness, ventilation and maintenance access is smooth. Water, electricity, steam and other utilities should be designed in advance according to the parameters of the equipment, so that the equipment can be installed and commissioned smoothly. The equipment should maintain sufficient spacing, to facilitate late operation and maintenance. In addition, priority should be given to industrial parks close to potato planting areas or with convenient transportation to reduce logistics costs.

Choose Suitable Equipment and Suppliers

When choosing frozen French fries making machine, the following points should be paid attention to:

- Equipment quality and stability;

- Whether it supports different capacity requirements;

- Whether to provide installation and commissioning services;

- Whether the equipment is equipped with technical support and after-sales guarantee.

Lonkia has many years of international project experience and can provide customized solutions for global customers, including equipment transportation, on-site installation and operation training services, helping you to build a worry-free plant.

Equipment installation and commissioning and technical training

After the equipment arrives at the factory, it must be accurately installed and electrically debugged by professional technicians to ensure that each piece of equipment is smoothly linked and the parameters are matched. Subsequently, we carry out trial production to verify and optimize the operation status of the whole frozen French fries production line. At the same time, the organization of staff training, explaining the operating specifications and maintenance knowledge, to improve the overall production efficiency and safety.

Overall, the construction of a frozen French fries production line is a systematic project, and each link directly affects the quality and production efficiency of the final product. Through the selection of high-quality equipment, reasonable planning and layout, professional installation and commissioning and perfect staff training, enterprises can achieve efficient and stable production goals. If you are looking for a reliable equipment supplier, Lonkia will be your reliable partner for your automatic frozen French fries plant.