Recently, customers from Russian food processing enterprises visited our French fries making machine factory to have a comprehensive tour and in-depth understanding of the whole line. This visit not only reflects the customer's recognition of our technical strength, but also lays a solid foundation for future cooperation between the two sides.

Automatic French Fries Production Line Attracts Customers' Attention

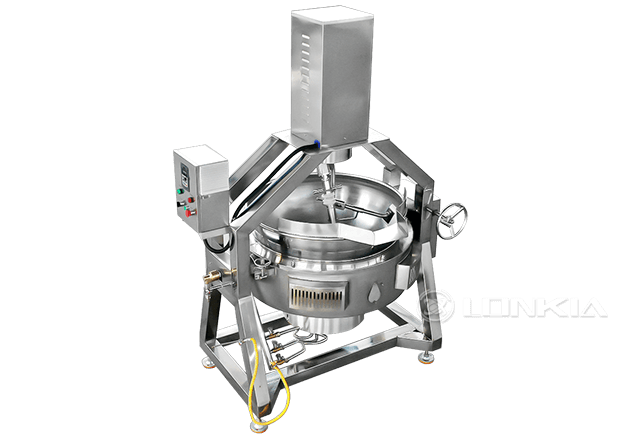

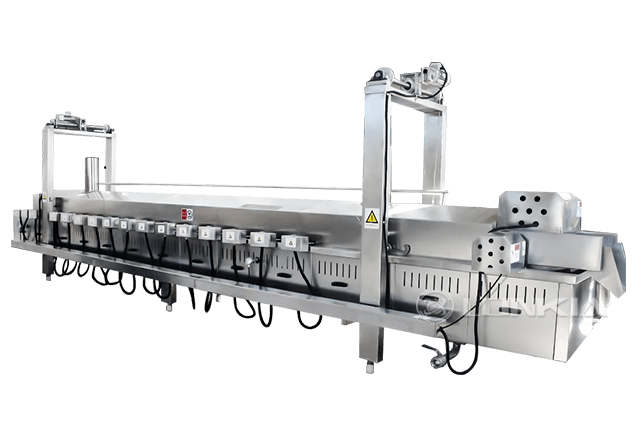

Lonkia team warmly received the customer and showed him the whole line from cleaning and peeling, cutting, blanching, dehydration, frying, cooling to packaging. The customer focused on the working condition of the core equipment, such as the inverter-controlled frying system, the intelligent temperature control device and the high-efficiency cooling module, and highly appreciated the continuous operation capability and energy-saving design of the equipment.

Mature and Stable Process, Adapting to Various Capacity Requirements

During the visit, the customer showed great interest in the modular structure of our production line. The French fries production line supports customization and can be flexibly configured to meet different output requirements from small and medium-sized processing plants to large-scale industrial production. At the same time, the main body of our automatic French fry maker is made of food-grade stainless steel, which complies with EU market standards and facilitates access to the Russian market.

Technical Explanations Help Customers Understand Machine Advantages

Lonkia engineers introduced in detail the operation flow, control system and daily maintenance of the whole line, especially emphasizing the advantages of the line in energy saving, safety and automation. After experiencing the simulation operation, the customer said, "This set of equipment is mature and compact, which is suitable for our company's long-term development needs of expanding production capacity in the future."

This visit not only deepened the customer's understanding of Lonkia's French fries production line, but also laid a good foundation for further cooperation between the two sides. Customers indicated that they plan to complete the project evaluation in the near future and then enter into the purchase negotiation stage. Lonkia will continue to provide efficient and reliable solutions for global food processing enterprises with high quality equipment and professional services.