Frying is one of the most important parts in the snack chip production process, and the cleanliness of the oil directly affects the quality of the finished product. Traditional frying equipment often suffers from accumulation of oil residue and deterioration of oil quality, which not only affects the taste and appearance of sweet potato chips, but also may lead to production line downtime or equipment damage. To solve these problems, modern sweet potato chips fryers are equipped with automatic filtration systems, which can effectively improve production efficiency and ensure food quality.

Advantages of automatic filtration systems

Improved oil stability

The biggest advantage of sweet potato chips fryer's automatic filtration systems is their ability to effectively remove impurities from the oil, such as debris and sediments generated during the frying process of sweet potato chips. Clean oil not only ensures the golden color and crispy taste of snack chips, but also prolongs the service life of the oil and reduces the need for frequent oil replacement, thus saving production costs.

Improve production efficiency

Traditional fryers require manual cleaning of impurities in the oil, which not only wastes time, but also leads to production interruptions. The automatic filtration system, however, can clean the oil in real time and automatically, avoiding manual intervention and ensuring the continuous operation of the production line to improve production efficiency.

Reduced equipment breakdowns

Accumulation of oil sludge and impurities can clog pipes or affect the heating system, leading to equipment breakdowns. The automatic filtration system can effectively prevent these problems from occurring, ensuring long-term stable operation of the equipment and reducing maintenance costs.

Automatic filtration system for Lonkia sweet potato chips fryer

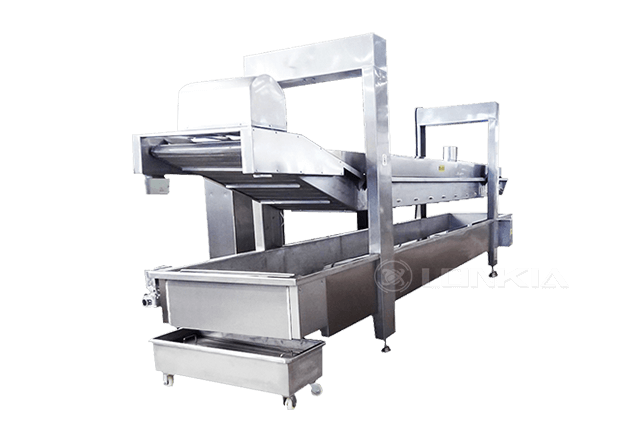

Lonkia's continuous fryer machines are equipped with an advanced automatic filtration system, which ensures the stability and cleanliness of the oil during the frying process by means of highly efficient oil circulation and filtration technology. Whether it's for oil temperature control or oil purification, Lonkia has carefully designed the system to ensure that every chip is fried to the desired result.

Lonkia's automatic filtration system not only improves frying efficiency, but also effectively reduces the cost of manual intervention and equipment maintenance frequency. Through innovative design, Lonkia is committed to providing customers with a smarter, more stable and cost-effective solution for potato chip frying, helping them to improve productivity and product quality. If you are looking for a high performance continuous fryer machine, Lonkia is the ideal choice.