Crispy, delicious potato chips are one of the world's favorite snacks, but have you ever wondered how an ordinary potato is transformed into a golden, tantalizing chip? Behind the scenes is actually a set of sophisticated chips production machine in silent operation.

Next, let's walk into this magical potato chips production line and see how it turns a potato into a piece of crispy and flavorful potato chips.

✅ Cleaning system: cleanliness is the beginning of deliciousness

The first step in potato chips production is to thoroughly clean the raw potato. Through the combination of spray washing machine and tumbling device, it can quickly strip the potato surface of soil and impurities to ensure food-grade cleanliness standards.

The high-pressure spray nozzles provide even coverage, and the automatic residue removal system ensures that the assembly line operates without downtime, laying a hygienic foundation for subsequent processing.

✅ Peeling and cutting: precise and efficient mechanical control

In the peeling section, chips production machine offers two mainstream solutions:

- Brush peeling machine: suitable for scenarios with large output and high requirements for skin removal. The potato skin is quickly peeled off by brushing and friction.

- Steam peeler: for users who seek high efficiency and high integrity. Utilizing high temperature steam to peel off the skin instantly, with high removal rate and small loss of raw materials.

After peeling, the potatoes are transported to the vegetable cutting machine. The high-efficiency rotary cutter adjusts the thickness of the slices to ensure that each slice is even and consistent, which is one of the key equipment to create a uniform taste.

✅ Blanching and drying: key processes for controlling color and taste

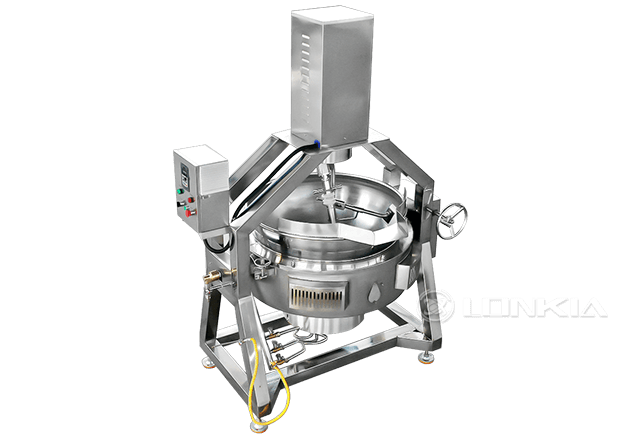

The cut potato slices need to be blanched to remove the starch and lock in the color. Lonkia provides vegetable blanching machine equipped with a precise temperature control system and an automatic time adjustment to ensure that the slices are processed uniformly and avoid oxidation and blackening.

Next, the potato slices enter the dryer. Through hot air circulation or far infrared heating, the surface moisture is removed to provide the ideal water content for subsequent frying, thus avoiding cracking or excessive oil absorption.

✅ Frying and degreasing: the golden step for crispy taste

Frying is the core step that determines the taste and color of potato chips. Lonkia's continuous fryer adopts thermostatic control and multi-point heat zones to ensure that each potato slice is evenly heated and fried until golden brown and crispy.

After frying, the fryer automatically enters the degreasing machine. Through high-speed centrifugal or air-cooling system to quickly remove excess oil on the surface, not only to improve the taste, but also to make the finished product more healthy and lighter.

✅ Seasoning: even flavoring, automated packaging

The last step is seasoning. The seasoning machine combines a rotating drum with a precise powder spraying system to make each chip evenly adsorbed with seasoning, whether it's classic salty flavor or special spices, all of which can achieve standardized output.

After seasoning, the finished product goes directly to the automatic packaging system to complete the weighing, sealing and labeling process.Lonkia's integrated design makes the production more efficient and saves a great deal of labor and time costs.

From cleaning to flavoring, the entire potato chips production line relies on the close collaboration of each functioning piece of equipment to form an automated system with high efficiency and low margin for error. chips production machines from Lonkia are what many food factories rely on to create high-quality snack foods.

If you're looking for chip processing equipment that improves efficiency, ensures finished product consistency, and is easy to maintain, feel free to contact us to learn more about Lonkia's solutions.