With the rise of the global fast food culture, French fries, as one of the most popular snacks, have seen rising market demand. As an important country in North Africa, Egypt has seen steady growth in economic development in recent years, and the fast food industry has gradually become an important consumer market. Therefore, the establishment of an efficient and automatic French fries production line can not only meet the growing domestic demand, but also inject new vitality into Egypt's food processing industry.

Potential for French fries in the Egyptian market

Egypt has a population of more than 100 million and most young people are attracted to fast food. With the accelerated pace of life, consumer demand for ready-to-eat food is increasing year by year, and French fries, as one of the main forces, have a promising market outlook. In addition, Egypt's geographical location, convenient transportation, not only to meet the domestic market demand, but also through the export of radiation in neighboring countries, for enterprises to open up a broader market.

Sufficient raw material resources

Egypt is one of the major potato growing countries in Africa, the annual output of potatoes is stable, diverse varieties, the quality is suitable for processing French fries. Especially in the seasonal export trough, a large number of high-quality potato resources need to be transformed into higher value-added products. Through the construction of automatic French fries production line, not only can the raw materials be transformed locally to reduce waste, but also pull the development of agricultural planting, transportation and cold chain logistics and other related industries, realizing the deep integration of agriculture and food industry.

Technical support for Lonkia French fries making machine

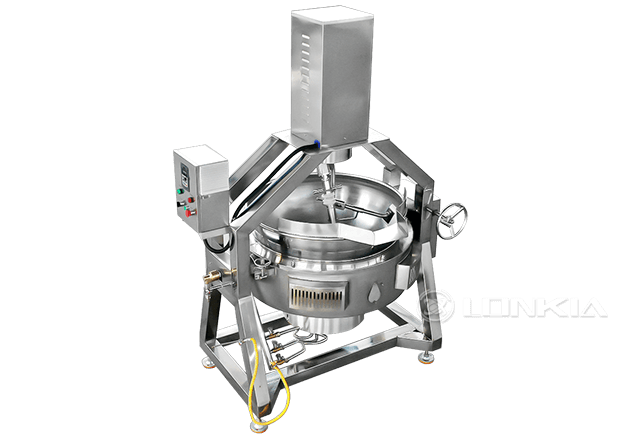

The introduction of automatic French fries production line is the key to improve production efficiency and ensure product quality. Lonkia French fries making machine greatly reduces labor cost and improves production efficiency at the same time through fully automated operation. The production line includes potato cleaning, peeling, cutting, rinsing, frying, cooling and many other steps to ensure that each french fry meets the standard.

- Automated control: The automated control system allows for precise temperature and time control, ensuring consistent taste and appearance of the fries.

- Energy efficient: Lonkia French fries production line utilizes advanced energy-saving technology to reduce energy consumption, lower production costs and help companies increase profitability.

- Easy to operate: The entire French fries manufacturing process requires almost no human intervention and only a small number of operators for management and maintenance, greatly reducing labor costs and management difficulties.

To sum up, building an automatic French fries production line in Egypt is a feasible way to meet the local market demand and improve production efficiency and product quality through modernized equipment, and Lonkia French fries making machine, with its advanced technology and efficient production capacity, can help Egyptian enterprises to occupy a position in the highly competitive market.