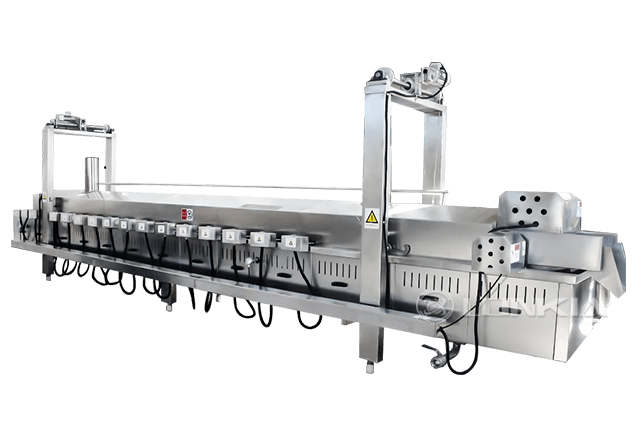

In the food processing industry, choosing a suitable continuous frying machine is crucial for improving product quality and production efficiency. Different types of materials on the structure of the frying equipment, temperature control, conveying methods have different requirements, this article will introduce from a variety of perspectives on how to scientifically select the type, to help enterprises to achieve efficient frying.

Different Materials on the of the Fryer Machine Structure Requirements

Frying vegetables, aquatic products, meat or soy products, its shape, moisture content, density and other different, resulting in different frying time and temperature required. For example, deep-frying eggplant requires the temperature to be maintained at about 180°C, and the material should be discharged quickly to prevent excessive oil absorption. Therefore, you should choose a continuous frying machine equipped with an automatic temperature control system and a precision frequency conversion conveyor system to ensure the stability of the frying process.

For fragile or light materials, such as bean skins and lotus root slices, it is recommended to choose a continuous fryer with a top-pressure mesh belt device to prevent floating and uneven heating, which affects the taste of the finished product.Lonkia can provide customized designs according to customers' needs to ensure that the equipment can maximize the adaptability to the site working conditions.

Flexible Control of Temperature and Frying Time

Different foodstuffs have different tolerances for temperature and time, so when choosing a continuous frying machine, you should pay attention to whether the equipment has a multi-segment temperature control function and a frying time adjustment system.Lonkia's brand of continuous fryers support PLC intelligent operation, which allows users to set the optimal parameters according to the different foodstuffs and ensures that each batch of products has the same color and texture.

Oil Circulation System and Oil Quality Assurance

High-quality continuous fryers should be equipped with an oil circulation system and oil residue filtering device. This not only reduces oil consumption, but also prevents oil deterioration due to dregs deposition, prolongs the oil life cycle, and improves product hygiene standards.Lonkia continuous deep fryers are designed with centrifugal filtration, which purifies the oil and grease in real time during operation and ensures the quality of the product.

Considering the Needs of Subsequent Production Lines

Continuous fryer is often not a stand-alone equipment, but a part of the whole automated production line. Lonkia can provide customers with a complete line of solutions to realize the integrated automatic control from raw materials to packaging, and improve the overall production capacity and efficiency.

Overall, the purchase of continuous frying machine is not only price comparison, but also from the product characteristics, structural configuration, temperature control system, oil management, etc. Lonkia specializes in the research and development of frying equipment production for many years, has a wealth of industry experience and technical accumulation, can provide customers with more scientific selection advice and customized solutions to help enterprises upgrade their production. For more information, please visit our official website or contact our sales team.