In the production of French fries, consistency of taste is an important indicator of product quality. Unlike traditional manual operation, LONKIA's French Fries Production Line effectively guarantees the crispiness, standardized shape and uniform taste of each french fry through advanced equipment configuration and precise process control.

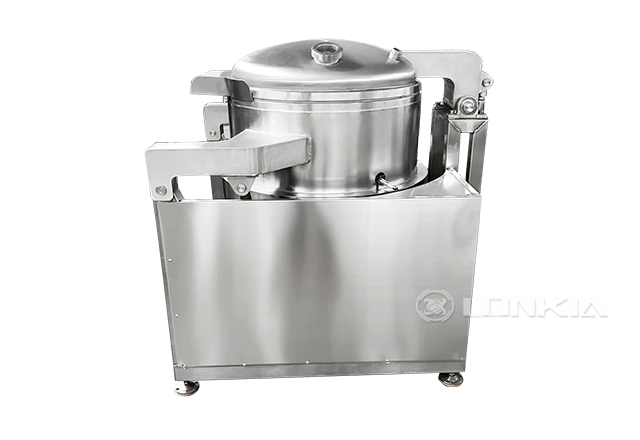

Precise Cutting to Ensure Uniformity of Size

LONKIA's wave French fry cutter, with its stainless steel construction and high-speed rotating knives, is capable of cutting potatoes of different sizes with precision. By adjusting the knife specifications, it ensures that each batch of fries maintains a consistent length and thickness, which provides a uniform basis for subsequent frying and seasoning, and avoids differences in frying texture caused by uneven sizes.

Stable Oil Temperature Control Brings Crispy Texture

Frying is the key to determining the taste of French fries, and LONKIA French fries production lines are equipped with continuous frying machines with automatic temperature control systems, which can monitor and adjust the oil temperature in real time to ensure that the frying process is completed at a constant temperature. The high precision temperature control not only avoids overfrying or underfrying, but also ensures that the French fries are crispy on the outside and soft on the inside, resulting in the ideal texture.

Continuous Turning and Precise Setting of Frying Time

In order to avoid uneven stacking of fries, LONKIA's frying section is designed with an automatic turning structure to ensure that each and every fry is evenly heated. At the same time, the adjustable conveyor speed allows customers to set the optimal frying time according to different product specifications, thus achieving flavor consistency in mass production.

Continuous Cooling Locks in Texture and Flavor

After frying, French fries need to be cooled down quickly in order to lock the crispy state after frying. The cooling system in LONKIA French fries production line adopts a combination of air-cooling or water-cooling to help the finished products stabilize at the ideal temperature quickly, prevent softening and deformation, and improve the stability of the finished products for storage and transportation.

Professional French Fries Production Line for Sale

LONKIA always focuses on the process improvement and technology optimization of food processing equipment, and has accumulated rich experience in the design and manufacture of French fries production line. Its products are widely used in many frozen food factories and chain food brands, and have gained the trust of customers all over the world due to their stable operation, guaranteed taste and high degree of automation. If you want to upgrade your existing equipment or start your own French fries making machine factory, feel free to contact a professional French fries production line manufacturers and we will actively provide you with customized solutions.