The demand for French fries continues to grow globally, and more and more food processing enterprises are paying attention to the investment and layout of French fries production line. When purchasing this type of production equipment, the price naturally becomes one of the most concerned factors for buyers. So, what exactly determines the French fries maker machine price? The following points are crucial.

Equipment configuration determines the cost structure

A complete French fries production line usually includes cleaning, peeling, cutting, blanching, dehydration, deep-frying, packaging and so on. There are big differences in equipment configuration among different manufacturers, such as whether it is equipped with automatic control system, continuous fryer and tunnel-type quick-freezing machine, etc. These configurations directly affect the whole production line. These configurations directly affect the manufacturing cost and functional performance of the entire production line, which also forms the price difference.

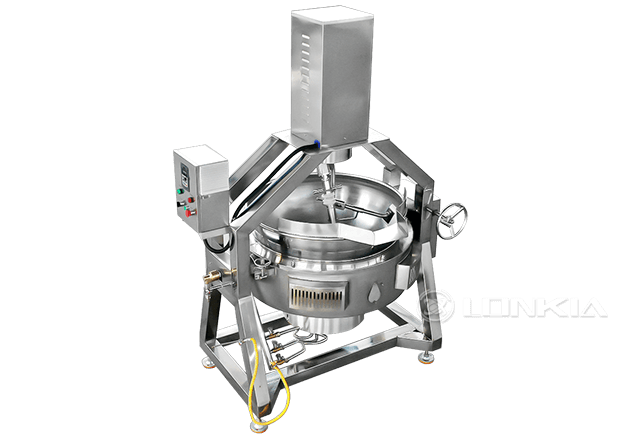

Material and processing technology are the key influence points

French fries making machine is in contact with grease and high temperature for a long period of time, which has high requirements on the hygiene and durability of the material. High-quality equipment is generally used in food-grade stainless steel, and in the welding, polishing, rust and other processes more fine, these technical improvements will significantly increase manufacturing costs, but also effectively enhance the stability and service life of the equipment.

The degree of automation affects the operational efficiency

Currently the mainstream French fries production line most tend to automation, such as PLC control systems, automatic monitoring, intelligent alarms and other features can reduce labor costs, improve production efficiency. This type of intelligent design although the initial investment is higher, but in the long-term operation can significantly improve the rate of return, the price will naturally rise accordingly.

Brand and after-sales service are also part of the cost

Choosing a strong frozen French fries production line manufacturer can largely avoid subsequent maintenance problems. For example, Lonkia, as a professional food processing machinery manufacturer, provides complete line delivery, one-stop service and localized after-sales technical support, which protects users' stable operation after purchase. Brand added value and after-sales protection are usually reflected in the price as well.

The French fries production line price is not a single decision, but the result of a number of factors. In actual purchasing, buyers should comprehensively consider the equipment configuration, manufacturing materials, automation level, and supplier service capability, rather than focusing only on the initial offer. Choosing a set of cost-effective production line with stable performance can ensure the long-term stable development of the enterprise.Lonkia is always committed to providing customers with high-quality, high-efficiency French fries manufacturing process solutions, welcome to come to consult and customize.