In the garlic processing industry, peeling is one of the most basic and time-consuming aspects. Many start-up processing plants still rely on manual peeling, which is not only inefficient, but also labor-intensive, with poor processing consistency. As the processing demand rises, more and more enterprises choose to introduce mechanized equipment, especially the 300-500kg/h garlic peeling machine with stable output, to replace the traditional manual operation. This article will take you to understand the actual benefits of the upgrade and the advantages of the equipment.

Dramatic Increase in Output, Solving the Labor Bottleneck

The average efficiency of manual garlic peeling is about 20-30kg/person/hour, while a fully automated garlic peeling machine can easily complete the workload of more than 10 people in one hour, greatly improving the production efficiency.This kind of equipment supplied by Lonkia supports continuous feeding, with a stable output and no need for frequent stops to change people, which greatly alleviates the problem of labor constraints.

High Peeling Rate and Consistent Finished Product

Compared with manual operation, mechanical equipment performs better in terms of peeling uniformity and finished product neatness. Lonkia's industrial garlic peeler adopts the dry pneumatic peeling principle, which realizes non-destructive peeling through high-pressure airflow and achieves a peeling rate of more than 95%, which effectively maintains the integrity of the cloves and is suitable for subsequent slicing, sauces, or freezing processing.

Easy to Operate and Maintain

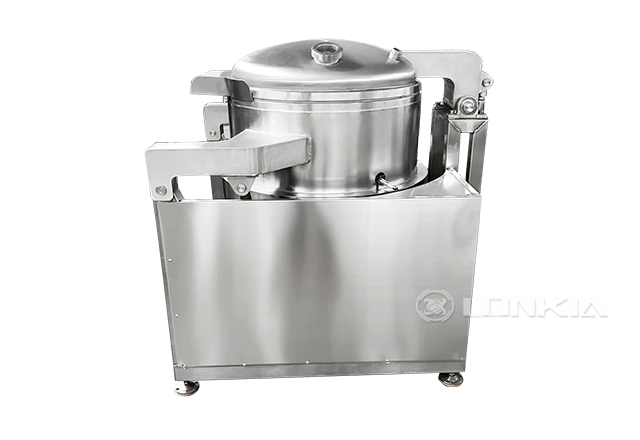

Garlic peeling machine has a compact structure, equipped with intelligent control panel, workers can be skillfully operated after simple training. The whole machine is made of stainless steel, which is easy to clean and has a long maintenance cycle, and only some of the wearing parts need to be checked routinely.

Adapting to the Production Rhythm and Guaranteeing Order Delivery

Increased production not only means higher efficiency, but more critically, it can guarantee the delivery cycle and customer satisfaction. With the introduction of the garlic peeler, the garlic peeling production line's operational efficiency has steadily improved and the processing cycle has been shortened to better cope with order peaks and enhance the company's delivery capability and market responsiveness.

Lonkia Helps You Realize the Transformation and Upgrading of Processing

Lonkia specializes in the research, development and manufacturing of mechanical processing equipment for vegetables, fruits and agricultural products, and provides complete line solutions including garlic peeling machines. Our equipment has been widely used in Southeast Asia, the Middle East, South America and other regions, trusted by customers. For more information about the output and model of garlic peeling machine, welcome to visit our official website or contact our sales manager for detailed parameters and quotation. We will recommend the most suitable equipment program according to your actual needs