How to Maintain the French Fries Production Line for Long-Term Use?

As an important equipment in the food processing industry, the stable operation and long-term use of the French fries production line is crucial to the benefits of the enterprise. Good maintenance can not only reduce the failure rate, but also ensure product quality and production efficiency. This article will focus on how to scientifically maintain the key equipment in the frozen French fries production line, to help enterprises achieve long-term operation of the equipment.

Learn MoreHow to Start An Automatic Frozen French Fries Plant in Your Country: Complete Setup Guide

Frozen French fries have become a food product that continues to grow in demand in the global marketplace due to their convenience, taste and ease of preservation. More and more business owners and investors are looking to invest in automatic frozen French fries plant in their home country to cater to the local market or export business. In this article, we will explain in detail the steps involved in setting up French fries making machine factory in your country to help you get your project off the ground…

Learn MoreHow Does Production Capacity Affect the Price of Frozen Potato Production Line?

Frozen potato production line is a set of automated processing equipment integrating cleaning, peeling, cutting, blanching, cooling, deep-frying, degreasing, freezing and packaging. For food enterprises that want to put into production frozen French fries, the choice of capacity is directly related to the configuration and price of the entire production line. This article will focus on this core issue, analyze the direct correlation between capacity and price, to help enterprises make more reasonable…

Learn MoreHow to Maximize the Output of Frozen French Fries Processing Line?

In the food processing industry, French fries have become a popular product due to its wide market demand. To efficiently produce frozen French fries with stable quality, a high-performance frozen French fries processing line is the key. By rationally configuring equipment and optimizing operating procedures, companies can significantly increase production capacity and reduce operating costs.

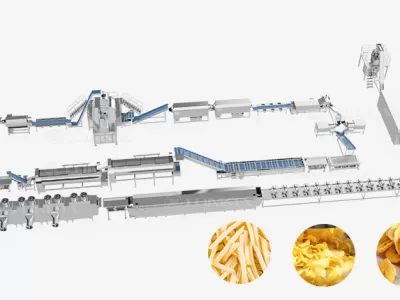

Learn MoreFrozen French Fries Production Line

The Frozen French Fries Production Line is a state-of-the-art system designed to process up to 5,000 kg of potatoes per hour, ensuring high-quality, crispy fries. This fully automated line encompasses washing, peeling, slicing, blanching, frying, and freezing stages. Utilizing Individual Quick Freezing (IQF) technology, it locks in flavor and texture, with freezing times reduced to approximately 3-5 minutes, depending on the cut thickness, maintaining the fries' nutritional value and freshness.

Learn More