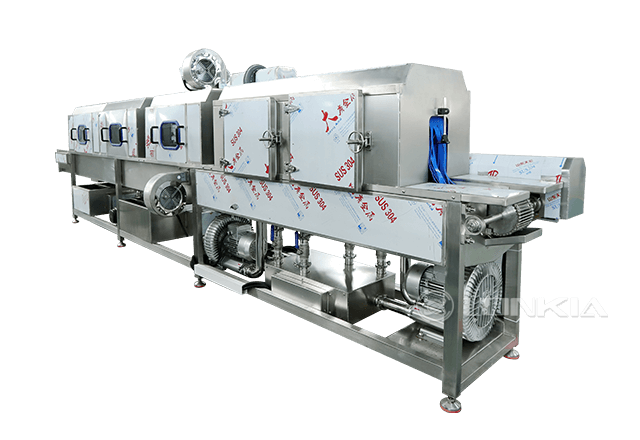

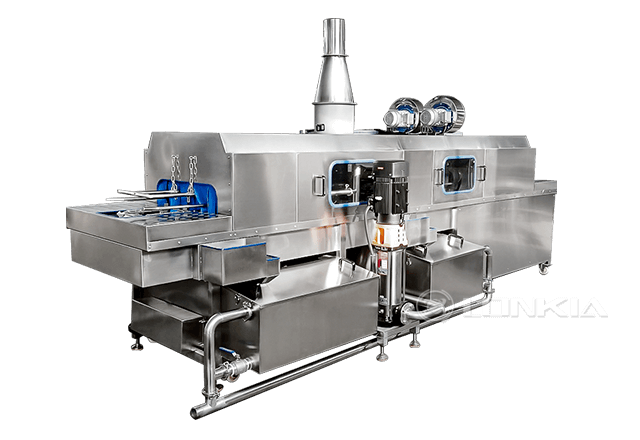

With increased awareness of food safety, especially in the meat processing industry, the choice of cleaning equipment has become particularly important. Auto crate washing machine, as a kind of automatic cleaning equipment, is widely used in the meat processing field, its high efficiency, thorough cleaning ability to help enterprises to meet the strict health requirements, to ensure the quality of food on the production line. In this article, we will discuss the application of poultry washers in the meat processing industry, focusing on the design features and functions of the machines themselves.

Efficient cleaning performance

During meat processing, crates typically accumulate large amounts of blood, grease and meat residue. Plastic crate washers are able to effectively remove this dirt by utilizing strong water flow and a multi-stage cleaning process. During the cleaning process, the equipment's high-temperature water flow combined with the cleaning agent can penetrate into every corner and thoroughly clean the inside and outside of the crate. The high efficiency of the equipment ensures the consistency of the cleaning effect and avoids the hygienic hazards brought by manual cleaning.

Automated operation to enhance productivity

In the meat processing industry, productivity is critical. Auto crate washing machines have a fully automated operating system that feeds crates into the washing area via an automated conveyor belt and sends them out automatically after multiple washing stages. No operator intervention is required, reducing labor costs and cleaning time. At the same time, the application of automated system makes the cleaning process more stable, reduces human error and further improves the overall efficiency of the production line.

Adaptable to meet diverse needs

Meat processing plants often have diverse cleaning needs in the production environment, such as different sizes of plastic crates requiring different cleaning solutions. The flexible design of the poultry washer allows for the adjustment of cleaning parameters, such as water temperature, cleaning time and water pressure, according to actual needs. In addition, the modular design of the equipment allows the machine to be flexibly adjusted according to the layout of the plant to meet the needs of different production lines.

Enhancing hygiene standards

The meat processing industry has strict requirements for hygiene standards, especially before the product enters the market, and it is important to ensure that all equipment meets food-grade hygiene standards. Plastic crate washers are made of stainless steel on both the inside and outside surfaces, ensuring that they are easy to clean and corrosion resistant. During the cleaning process, the machine is able to effectively remove all kinds of pollutants generated during meat processing, ensuring that the crate meets the hygiene standard after cleaning, avoiding the breeding of bacteria and cross contamination.

Overall, the application of auto crate washing machine in the meat processing industry not only improves the cleaning efficiency, but also ensures the hygiene and safety of the products. Its efficient cleaning ability, automated operation, adaptable design and compliance with food safety standards make it an indispensable piece of equipment for meat processing plants. By using plastic crate washers, companies are able to improve productivity and reduce labor costs while ensuring food safety.