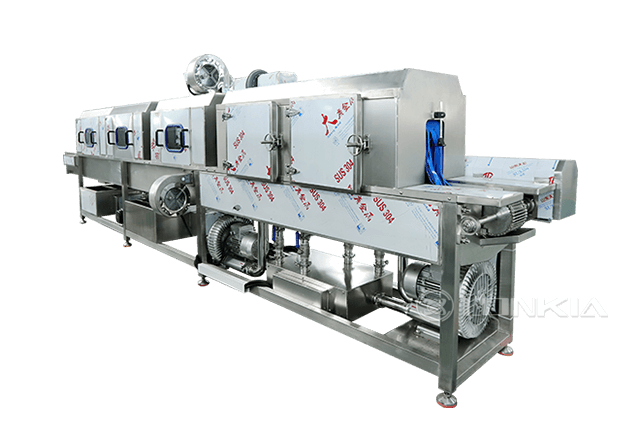

Industrial crate washing machine is an indispensable and important equipment in food processing, logistics and warehousing industries, which can effectively improve the cleaning efficiency and hygiene standards. However, in order to ensure the efficient operation of the equipment and extend its service life, regular maintenance is essential. In this article, we will provide you with a detailed maintenance guide for industrial crate washers to help you properly maintain your equipment.

Daily cleaning and inspection

After each use, you should clean your industrial crate washing machine. First, turn off the power to the unit and inspect the surface of the unit for any dirt or residue. Use detergent and soft cloth to wipe the machine body, avoid using rough tools or chemical cleaners that may damage the equipment shell. In particular, the spray system, inlet and outlet ports and other places that are prone to accumulating dirt should be cleaned in a focused manner.

In addition, regularly check whether the water pipe is leaking or clogged, clean the filter in time to ensure smooth water flow, to avoid affecting the cleaning effect.

Regularly check the mechanical parts

Crate washer machine consists of several mechanical parts, including the transmission system, nozzle, pump, etc. The state of these parts directly affects the normal operation of the equipment. Regularly check whether the belt and gears of the transmission system are loose or worn, and tighten or replace them if necessary. For pumps and other wear parts, it is recommended that they be replaced regularly according to the frequency of use to prevent failures caused by excessive wear.

Spray nozzles and water flow pipes are an important part of the basket washer, and the spray nozzles should be checked regularly for clogging. If the water coming out of the nozzle is uneven or the pressure is too low, it may affect the cleaning effect and should be cleaned or replaced in time.

Check the electrical system

The electrical system is the core component of the industrial crate washing machine, to ensure the normal operation of the electrical system is the key to maintain the stable operation of the equipment. Regularly check the connection status of the cables in the electric control box to ensure that there is no looseness, wear and tear or aging. The buttons and displays of the control panel should be cleaned to avoid the accumulation of dust leading to poor contact.

In addition, electronic components such as PLC control systems and sensors should be systematically tested on a regular basis to ensure their accurate operation. If any abnormalities are found, professional technicians should be contacted for repairs.

Overall, with proper daily cleaning, regular inspections and timely maintenance, crate washers can maintain efficient operation over a long period of time, reduce malfunctions and improve work efficiency. Hopefully, with the maintenance guide in this article, you will be able to better maintain and use your basket washing machine to ensure its long-term stable operation.