In the modern food processing industry, potato chips, as a popular leisure food, put forward higher requirements for line efficiency and product consistency. Traditional manual or semi-automatic equipment is no longer able to meet the demand for large-volume, standardized production. Fully automatic potato chips making machine significantly improves the overall capacity efficiency through intelligent design and integrated process, becoming the ideal choice for many food processing enterprises.

Integrated Continuous Process Reduces Manual Intervention

Fully automatic potato chips making machine integrates several links such as cleaning, peeling, slicing, blanching, deep-frying, seasoning and packaging in one production line, realizing continuous operation. Operators only need to carry out raw material placement and basic monitoring, which significantly reduces labor costs, avoids human error in operation, and ensures a stable and efficient production process.

Precise Control System Improves Product Consistency

The potato chips production line is equipped with a PLC control system and multiple sets of sensors, which can realize real-time monitoring and precise control of key parameters such as oil temperature, conveying speed and slice thickness. For example, the error of frying temperature can be controlled within ±1℃, which ensures that each batch of potato chips has the same color and taste. This high degree of consistency is particularly important in branded production, helping to improve customer satisfaction and market competitiveness.

Modular Structure Facilitates Maintenance and Adjustment

The potato chip production line's modular design facilitates quick knife changes, pipe cleaning and adjustment of operating parameters. Users can flexibly configure the production rhythm according to the size of raw materials and production demand, avoiding idle equipment or insufficient capacity. Meanwhile, the system has built-in automatic fault diagnosis function, which can provide early warning and reduce downtime.

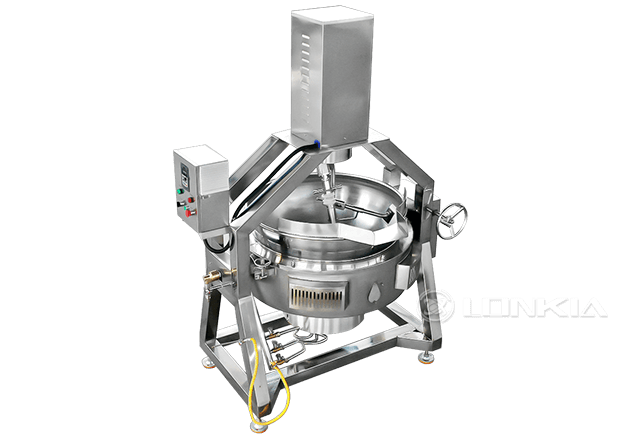

Energy-efficient Frying System

The fully automatic frying unit is equipped with a high-efficiency heat exchanger and dregs filtration system, which reduces oil consumption and impurity deposits while maintaining frying results. This design not only improves frying speed, but also extends the oil life cycle, helping to reduce operating costs.

Lonkia Offers High-performance Solutions

Lonkia, as a professional potato chips line manufacturer, has accumulated a wealth of engineering experience in the field of fully automatic potato chip machines. We provide complete service solutions from selection and design, customized production to after-sales installation, and are committed to building efficient and reliable potato chip production systems for our customers, helping enterprises to rapidly increase production capacity and enhance market competitiveness. You can contact us at any time to get efficient and customized potato chip production solutions.