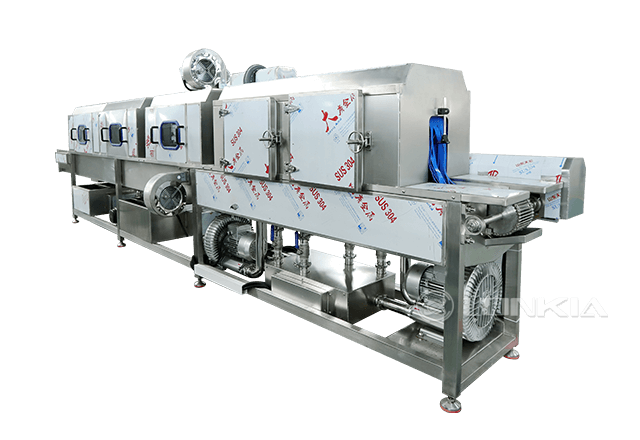

The pallet cleaning machine is a machine designed to provide cleaning services for industrial production. It uses water and detergent to thoroughly clean and purify industrial pallets from contaminants such as oil and food residues.

The pallet cleaning machine has the following main features:

- Efficient cleaning: By using high-pressure water flow and high-temperature water, the tray cleaning machine can quickly and effectively remove oil stains, food residues and other contaminants, thereby greatly improving production efficiency.

- Automated operation: The pallet cleaning machine adopts an automated operation process, which can reduce manual labor and improve production efficiency.

- Hygienic guarantee: The pallet cleaning machine can effectively kill bacteria and diseases by using detergent and high-temperature water.

- The pallet cleaning machine is a machine specially used to clean industrial pallets. It mainly uses water and detergent to complete the cleaning work.

- Clean the tray: By using high-pressure water flow, high-temperature water and detergent, the tray can be effectively cleaned to remove oil stains, food residues, etc.

- Improve work efficiency: Through automated cleaning processes, cleaning efficiency can be greatly improved and manual labor can be reduced.

- Ensure hygiene: By using detergent and high-temperature water, bacteria and viruses can be effectively killed to ensure the hygiene of the tray.

- Environmental protection: Pallet cleaning machines usually use circulating water systems, which can effectively reduce water waste and protect the environment.

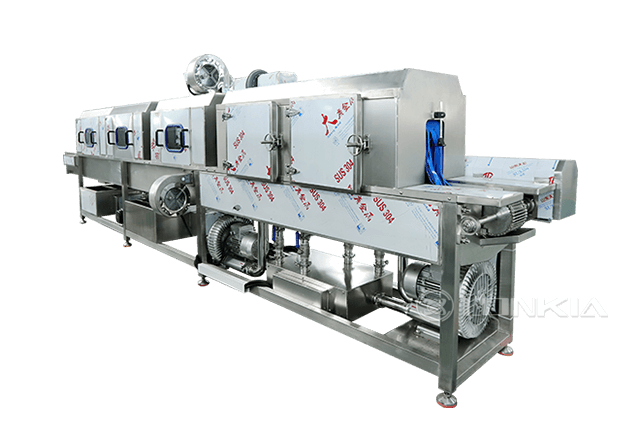

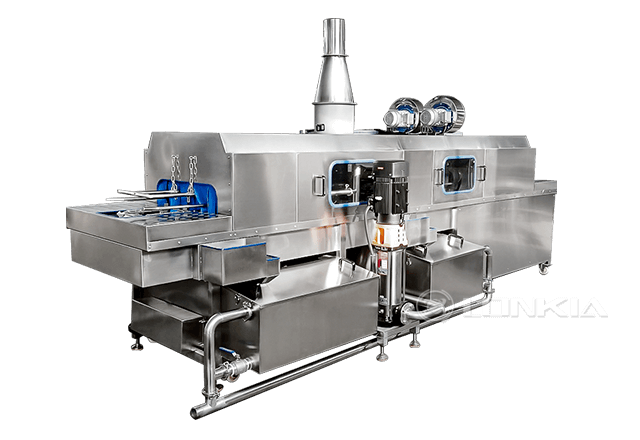

The fully automatic tray cleaning and drying line is an automated production line that is mainly used for cleaning and drying items in food, tableware, medical equipment and other industries. The working principle of this assembly line is to place items on pallets, and then go through a series of cleaning and drying procedures with automated equipment, ultimately achieving efficient cleaning and drying of the items.

The fully automatic pallet cleaning and drying line has the following characteristics: high efficiency, saving manpower, improving productivity, and ensuring that items are clean and hygienic. Each process of the assembly line is automated, which can effectively improve production efficiency; the operation of the assembly line is simple and convenient, which can reduce labor costs; the cleaning and drying procedures of the assembly line comply with hygienic standards, ensuring that items are cleaned through high-pressure water flow and The function of friction removes stains and residues on the surface of items; the dryer is the third process, which dries items through high-temperature hot air to ensure that items are dry and tidy; the water treatment system is to ensure the quality of water used in the assembly line cleaning process. It can reduce environmental pollution; the electrical control system controls and monitors the entire assembly line to ensure the normal operation of the assembly line.

The fully automatic pallet cleaning and drying line has the characteristics of high efficiency, environmental protection, and automation, which can greatly improve production efficiency and quality. It is one of the indispensable equipment for production enterprises. At the same time, the assembly line is simple to operate and maintain, and is suitable for large-scale production.

In general, the fully automatic pallet cleaning and drying line is an efficient, environmentally friendly, and automated article cleaning and drying equipment, which has brought great improvements and improvements to manufacturing companies.

With the continuous development of the logistics industry, the use of pallets as the main tool for cargo storage and transportation continues to increase. However, pallets will inevitably become contaminated and worn during use, so they require regular cleaning and maintenance. The traditional pallet cleaning method is mostly manual cleaning, which has low work efficiency, high cost, and has hygiene problems. For this reason, fully automatic depalletizing and stacking pallet cleaning equipment came into being.