In the garlic processing industry, improving production efficiency and guaranteeing product quality are the goals that enterprises are constantly pursuing. Garlic peeling line as an important equipment in automated production, how to expand the output without affecting the quality of peeling is a concern for many processing plants. In this article, we will introduce how to optimize the garlic peeling line equipment, both to improve production, but also to ensure the peeling effect.

Precise adjustment of equipment parameters

The output of garlic peeling line is closely related to the operating parameters of the equipment, including peeling temperature, wind strength, peeling time and so on. By precisely adjusting these parameters, the processing speed can be increased while ensuring the peeling effect. For example, appropriately increasing the wind strength and adjusting the peeling time can effectively improve the processing speed, but at the same time, it is also necessary to keep the garlic skin intact to avoid damage.

Optimize the design of the wind drying system

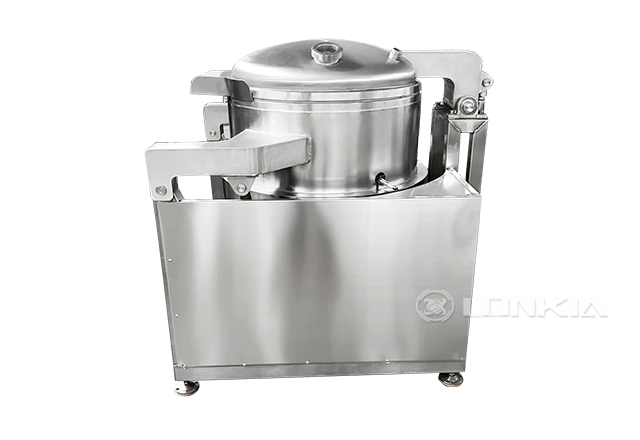

The design of the wind drying system of the garlic peeling processing line is the key to improve the yield. By optimizing the design of the wind system, we can ensure that the garlic can be dried quickly and evenly after peeling, thus improving the overall working efficiency. Lonkia peeling line adopts advanced air-drying technology, which enables the garlic to finish drying in a short period of time, thus reducing the waiting time during the production process, and further improving the overall yield.

Precise deployment of automation control system

The automation control system plays a crucial role in enhancing the output of the garlic peeling line. Through automation control, the equipment can automatically adjust the working speed and output according to different production needs, minimizing human intervention and keeping the production line running efficiently. Lonkia's peeling line is equipped with an intelligent control system that adjusts the operation according to the real-time data, ensuring stable operation of the equipment and improving production efficiency.

Reduced downtime and maintenance costs

Regular maintenance and troubleshooting can significantly reduce downtime and increase the productivity of a garlic peeling production line. By optimizing the design of the equipment, reducing the use of wearing parts and extending the service life of the equipment, maintenance costs and downtime losses can be effectively reduced. In the process of use, ensure that the various parts of the garlic peeling line (such as the peeling device, conveyor belt, air drying system) run smoothly, and can continue to maintain a highly efficient production state.

To sum up, improving the output of garlic peeling line does not mean sacrificing quality. Precise adjustment of equipment parameters, optimized air-drying design, intelligent automatic control system and regular equipment maintenance are all effective means to improve the output of garlic peeling line. Through these optimization measures, it can ensure that the equipment operates at high output while still maintaining a high peeling rate and intact garlic skin to meet the market's dual requirements for garlic processing quality and efficiency.