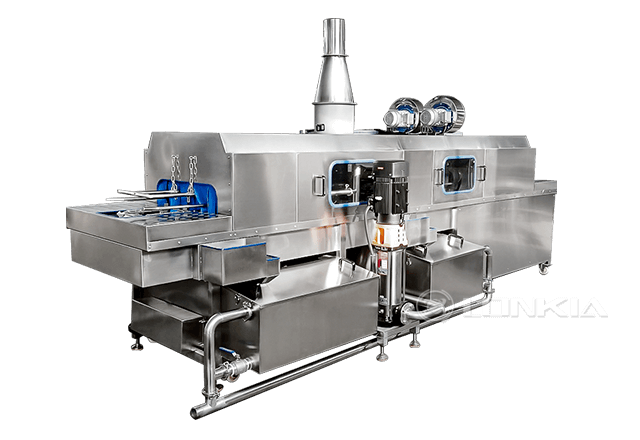

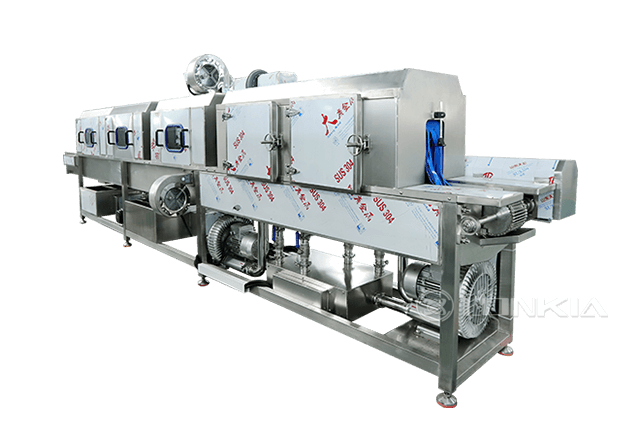

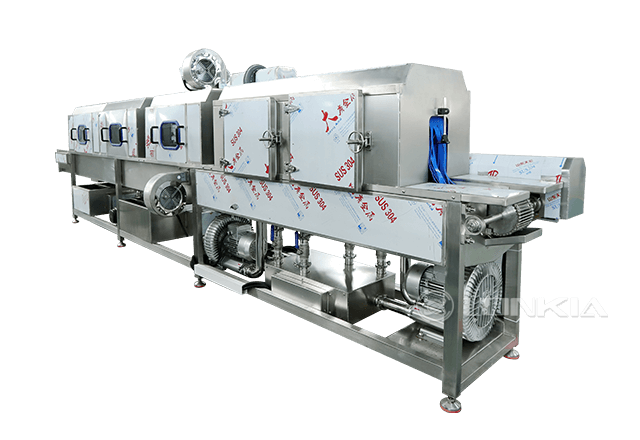

Industrial pallet washers are an essential piece of equipment in modern production lines, efficiently cleaning pallets of stains, food residues and bacteria to ensure a hygienic production environment. In order for the pallet washer to always work at its best, it is vital to optimize its performance. In this article, we will present some practical tips for optimizing your pallet washer machine to help you improve efficiency, reduce energy waste and extend equipment life.

Adjusting water pressure

Water flow pressure is one of the key factors affecting cleaning results and equipment efficiency. Excessive water pressure not only wastes a lot of water, but may also cause damage to the pallet; while too low a water pressure will lead to incomplete cleaning. Therefore, regular inspection and according to the cleaning requirements to adjust the water flow pressure to the appropriate range, can effectively improve the cleaning efficiency and reduce energy consumption. Most industrial pallet washers are equipped with a pressure adjustment function to ensure that the water flow can be accurately applied to the surface of the pallet to achieve the best cleaning results.

Optimize nozzle layout

The nozzle is the core component of the pallet washer machine and has a direct impact on the coverage of the water flow and the cleaning effect. Reasonable nozzle layout can ensure that the water flow is evenly distributed in all parts of the pallet, to avoid cleaning dead ends. Regularly checking the working condition of the nozzles to ensure that they are not clogged or worn out, and making reasonable adjustments according to the size and shape of the pallet can maximize the utilization efficiency of the water flow and improve the effectiveness of each cleaning.

Regular cleaning of the filtration system

Industrial pallet washers are usually equipped with a filtration system to recover impurities and dirt from the water. If the filtration system is clogged with dirt, it will directly affect the water flow and pressure, resulting in a decrease in cleaning efficiency. In order to ensure the long-term efficient operation of the equipment, the filtration system should be cleaned regularly to remove accumulated dirt and impurities and keep the water flowing smoothly. This not only improves cleaning efficiency, but also reduces the occurrence of system failures.

Regularly calibrate the temperature control system

Some industrial pallet washers are equipped with a temperature control system that can adjust the water temperature as needed. During the cleaning process, water temperatures that are too high or too low can affect the cleaning results. Too high a temperature can damage the surface of the pallet, while too low a temperature will not effectively remove stubborn stains. Therefore, regular calibration of the temperature control system to ensure that the water temperature is always maintained in the appropriate range can effectively improve the effectiveness of pallet cleaning and avoid equipment damage caused by temperature control malfunction.

By adjusting the water pressure, optimizing the nozzle layout, cleaning the filtration system, and calibrating the temperature control system, companies can significantly improve the efficiency of their industrial pallet washers. These optimizations not only ensure efficient operation, but also extend the life of the equipment and reduce maintenance costs. Regular maintenance of these optimizations will help companies keep their production lines running efficiently and ensure consistent cleaning results.