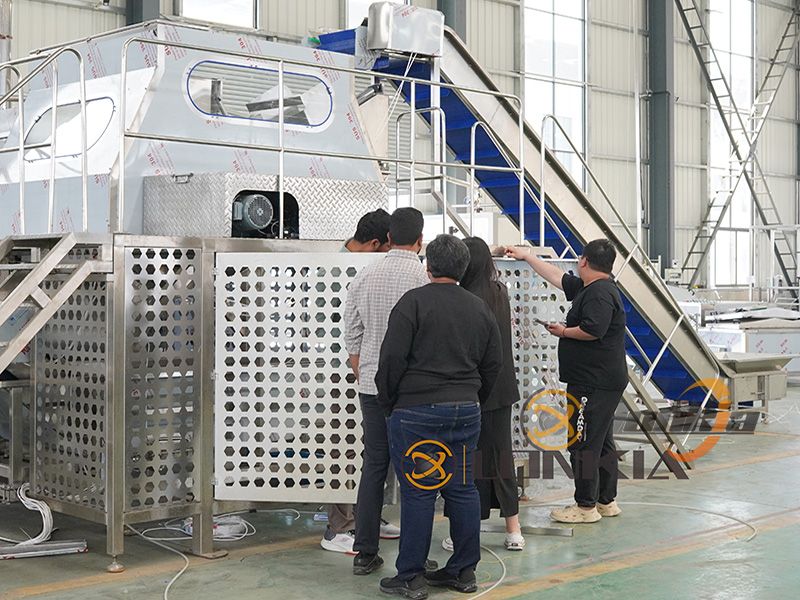

Recently, our factory was honored to receive important customers from India! In order to learn more about our steam peeling methods in food processing and fruit and vegetable processing equipment, the customer came to visit our factory and had a detailed communication with our business manager.

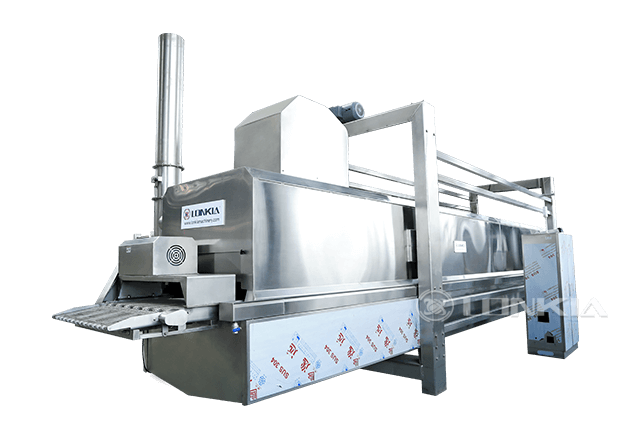

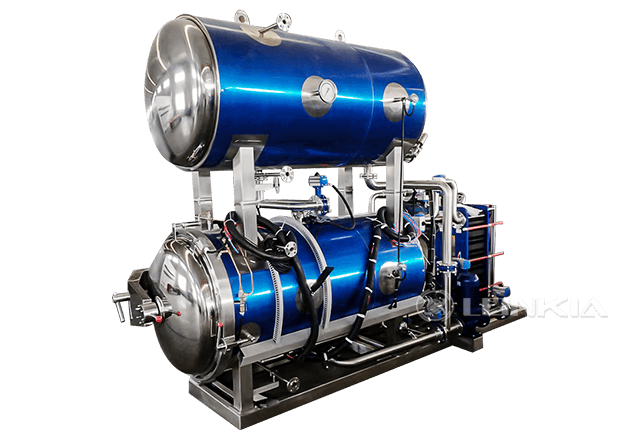

Accompanied by Lonkia's engineers, Indian customers learned about the working principle and technical parameters of the steam peeling machine. The equipment through high-pressure steam rapid heating of raw materials, so that fruit and vegetable skin quickly soften and burst off, applicable to potatoes, tomatoes, carrots and other root vegetables and fruit vegetables. The whole process not only improves the peeling efficiency, but also effectively reduces the loss of raw materials, ensuring the integrity of the appearance of the product and the retention of nutrients.

Advantages of Lonkia steam peeler

- Efficient peeling: Steam peeling machine uses high temperature steam to soften the skin of fruits and vegetables quickly, realizing efficient peeling, and the feeding capacity of each round can be up to 100-500 kilograms, which is suitable for the demand of mass production.

- Energy saving and environmental protection: Steam is used as the heating source, reducing energy consumption and environmental pollution.

- Easy to operate: Equipped with automatic control system, easy to operate, reduce manual intervention, improve work efficiency.

- Wide range of application: Applicable to a variety of fruits and vegetables peeling treatment, to meet the needs of different food processing enterprises.

Deepen the intention of cooperation

During the visit, Indian customers highly recognized the performance and quality of Lonkia steam peeling machine, and said they would definitely buy the advanced steam peeler and other fruit and vegetable processing equipment from our factory. The two sides carried out in-depth exchanges on the future mode of cooperation, technical support and after-sales service.

Lonkia always adheres to the concept of “quality-oriented, customer first”, and is committed to providing customers around the world with high-quality food processing equipment and perfect solutions. The visit of Indian customers not only deepened the understanding between both sides, but also laid a solid foundation for future cooperation.